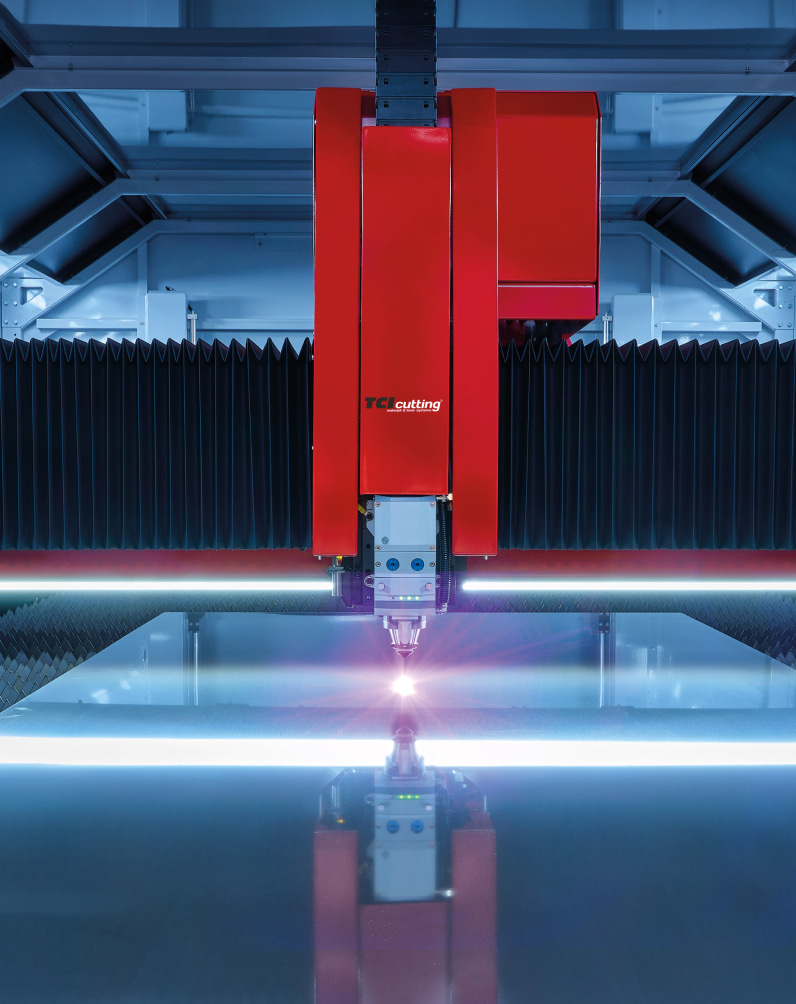

MAKE THE FUTURE YOURS

Main

Sectors

Industrial research

Steel industry

Industrial vehicles and transport

Chemistry and Petrochemistry

Food industry

BE PART OF THE FUTURE

Clients around the World

TCI CUTTING

We advise you

Contact our technical team. A specialist will contact you as soon as possible to advise you personally on everything you need.