LASER AND WATERJET CUTTING MACHINES

ENERGY INDUSTRY

ONE CLIENT, ONE SOLUTION.

Laser and waterjet cutting machines for the energy sector.

TCI Cutting offers multiple industrial cutting solutions for the energy sector. Machines of different cutting technologies, laser or waterjet, that cover the cutting of different materials for the energy industry: composite materials, technical fibers such as carbon fiber or glass, resin, polymers and all kind metalls.TCI Cutting cutting machines cover different volumes, formats and cutting needs with modular and flexible systems and XXL cutting machines.

TCI Cutting’s waterjet cutting systems provide an industrial cutting solution for various companies in the energy sector. The 2D laser cutting machine Smartline Fiber offers high quality cut and maximum flexibility, perfect for companies with changing needs, with different automation solutions to fave this sector’s challenges. For large volumes, the BP-H modular waterjet cutting machines cut large formats with the possibility of cutting in 5 axes and in 2D, 2D1/2 and 3D.

The Speedline Fiber laser cutting machine is the XXL format cutting system for large parts and very specific needs in the energy sector. 2D cutting with 2D1/2 option.

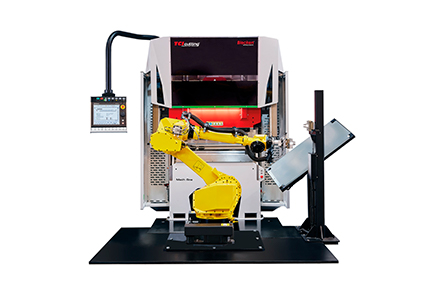

STATE-OF-THE-ART AUTOMATED SOLUTIONS

WE CREATE SMART FACTORIES

WITH AUTONOMOUS DECISION-MAKING

LASER AND WATERJET CUTTING MACHINES FOR ENERGY INDUSTRY

INCREASE YOUR PRODUCTIVITY

UP TO 80%

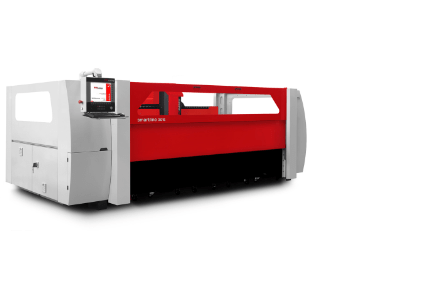

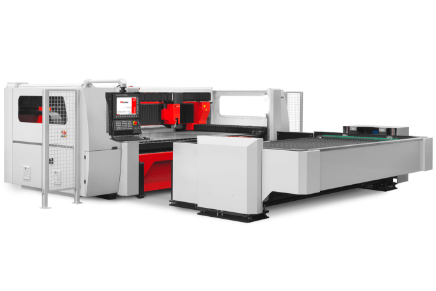

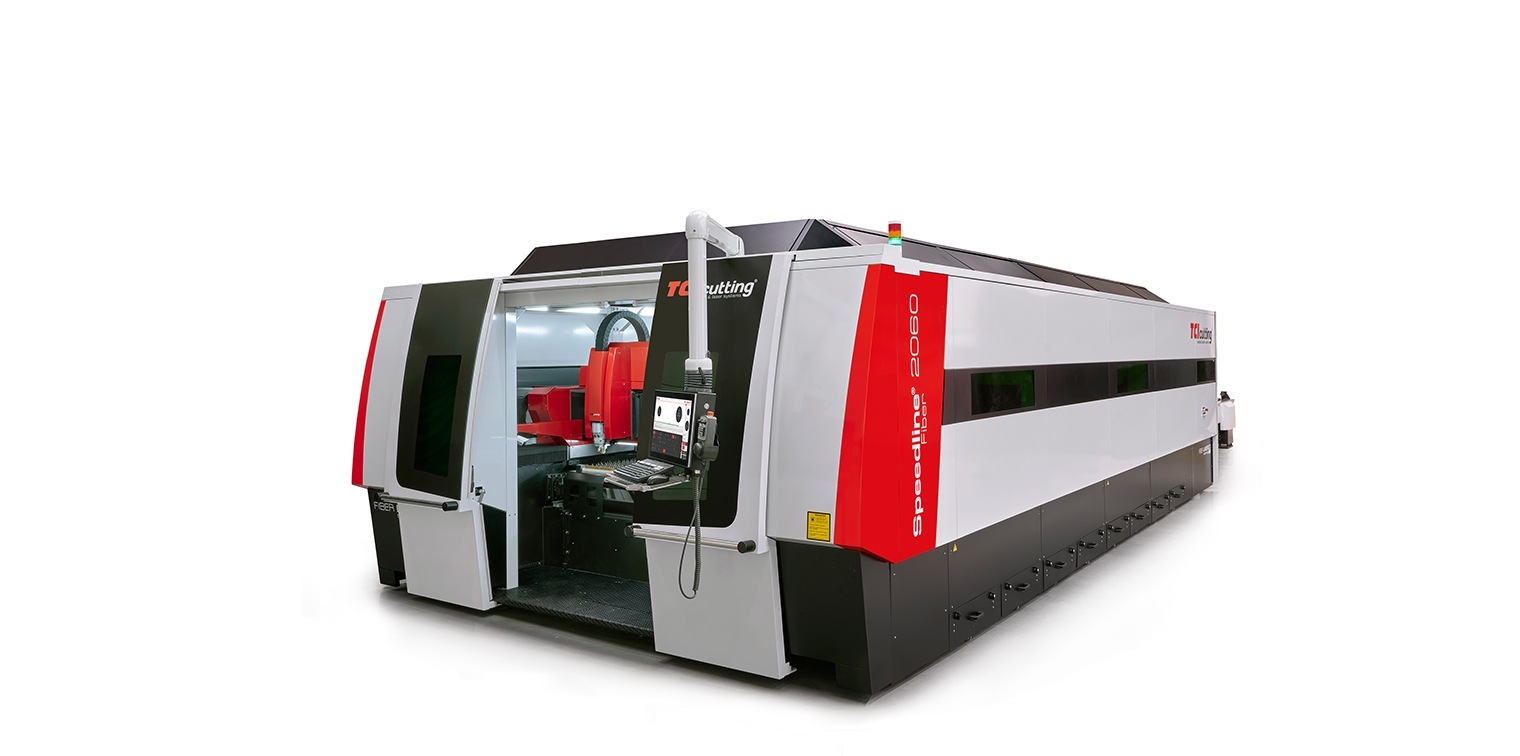

XXL FORMAT

Speedline Fiber

High power laser cutting machine, specially designed and developed for large formats and needs of the energy sector. 2D and optional 2D1/2 laser cutting technology for steel, stainless steel, aluminum, brass and copper, as well as plastics and fibers.

Speedline Fiber is a powerful machine that allows high quality cutting of medium and thick sheet metal and XXL formats. Get optimal energy efficiency in addition to maximum performance.

| Technical Data | |

|---|---|

| Maximum load | 8.400 kg |

| Heads | 1 or 2 (2D1/2 cutting option) |

| Maximum simultaneous positioning speed | 170 m/min |

| Maximum axial acceleration | 19,6 m/s2 (2G) |

| Machine tolerance VDI/DGQ3441 | ±0.05 mm/m |

| Repeatibility | ±0.025 mm |

| Power output | From 1 kW to 20 kW |

| Dimensions | multiple choices |

| Fully enclosed and cabined machine | Included |

| Smoke extraction system | Included |

| Cooling system | Included |

| Automatic table exchanger | Included |

| Automatic loader and unloader | Optional |

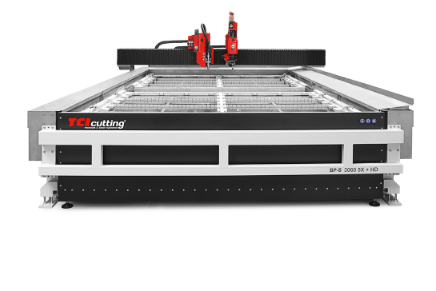

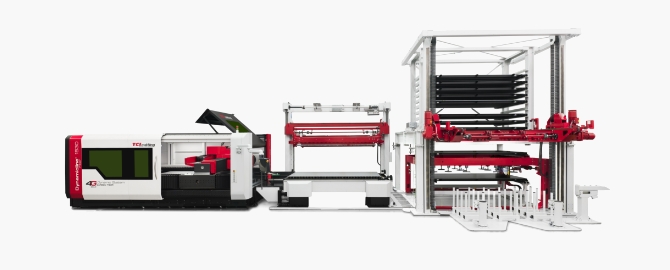

XXL FORMAT

BP-H

Waterjet cutting machine for large formats and volumes. All kinds of materials regardless their hardness. Without damaging the characteristics of the material.

This series is characterized by its great versatility and great possibilities for growth and adaptation to the needs of the energy sector. With a maximum height adjustment in its Z axis up to 500 mm. The BP-H machine allows up to 4 heads and 4 bridges. XXL cutting capacity. Low temperature cutting system avoiding thermal alterations. Low operating costs.

BP series is characterized by its bridge-type construction which provides great robustness, adaptability and flexibility and allows cutting large surfaces. Modularity.

| Technical data | |

|---|---|

| Maximum thickness of the part | 200 mm |

| Maximum permitted load | 790 kg/m2 |

| Number of cutting heads | 1 to 4 |

| Maximum number of bridges | 4 |

| Simultaneous max positioning speed | 85 m/min |

| Maximum cutting speed | 20 m/min |

| Machine tolerance according to VDI / DGQ 3441 | ±0.05 mm/m |

| Repetition accuracy | ±0.025 mm |

| Dimensions | multiple choices |

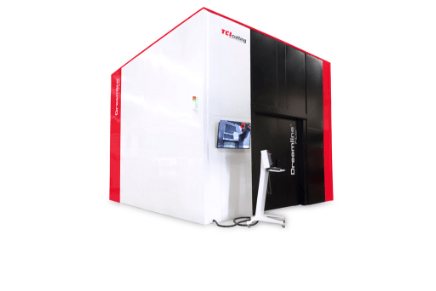

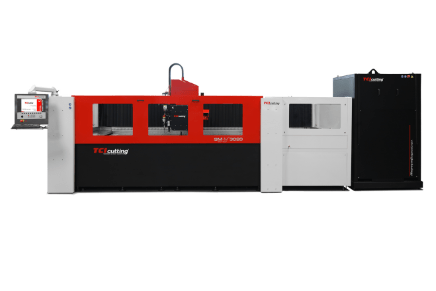

FLEXIBILITY

SMARTLINE FIBER

This series offers a perfect solution for companies with flexible processes that require continuous changes in production, both in parts and materials and thicknesses. Excellent laser cutting solution for short, long and flexible productive series and all type of materials. High production and excellent cutting quality for the energetic industry. Cutting of thin and medium thickness sheets of different metal materials.

Ideal cutting machine for those companies in the energy sector that need maximum flexibility and accessibility. 20% space saving in the factory, compact. Great energy efficiency due to its low electricity consumption. Available in powers from 1 kW to 15 kW.

| DATA SHEET | |

|---|---|

| Maximum load | 950 Kg |

| Heads | 1 |

| Maximum simultaneous positioning speed | 170 m/min |

| Maximum axial acceleration | 19,6 m/s2 (2G) |

| Machine tolerance VDI/DGQ3441 | ±0,05 mm/m |

| Repeatibility | ±0,025 mm |

| Power output | From 1 kW to 20 kW |

| Dimensions | 3.000×1.500×100 mm |

| Fully enclosed and cabined machine | Included |

| Smoke extraction system | Included |

| Cooling system | Included |

| Automatic table exchanger | Included |

| Automatic loader and unloader | Optional |

PRODUCTION

ENGINEERING

TCI Cutting offers an engineering service that diagnoses the optimal level of automation for your company and it guides you through the whole process of implementation in a modular way. We are your long-term technological partner.One client, one solution. Maximum quality and speed of implementation. Direct impact in ROI.

Transform your company into a Smart Factory and optimise your automation level with our Production Management Intelligent Software.

Tailor-made automated productive processes

Evaluation, diagnosis and technical report by our experts.

Automation implementation project

One client, one solution.

More productive and

autonomous machines

Full integration.

Management Intelligent Software

Production optimal management.

Smart

Factory

Smart factories. Industrial automation.Autonomous decision-making.

BE PART OF THE FUTURE

Clients around the World

Download Technical Data

Smartline Fiber

Download Technical Data

BP-H Series

Download Technical Data

Speedline Fiber

Download the complete catalog of solutions