INDUSTRIAL CUTTING MACHINES

Cutting machines for the defense sector

ONE CLIENT, ONE SOLUTION.

The defense and military sector needs to satisfy specific industrial cutting demands and needs by using a wide range of materials for multiple applications of technological interest . The sector, in constant technological evolution, needs to cut materials with very specific specifications and applications, such as armox for example, which are commonly used in this market niche and which must meet a series of very specific requirements.

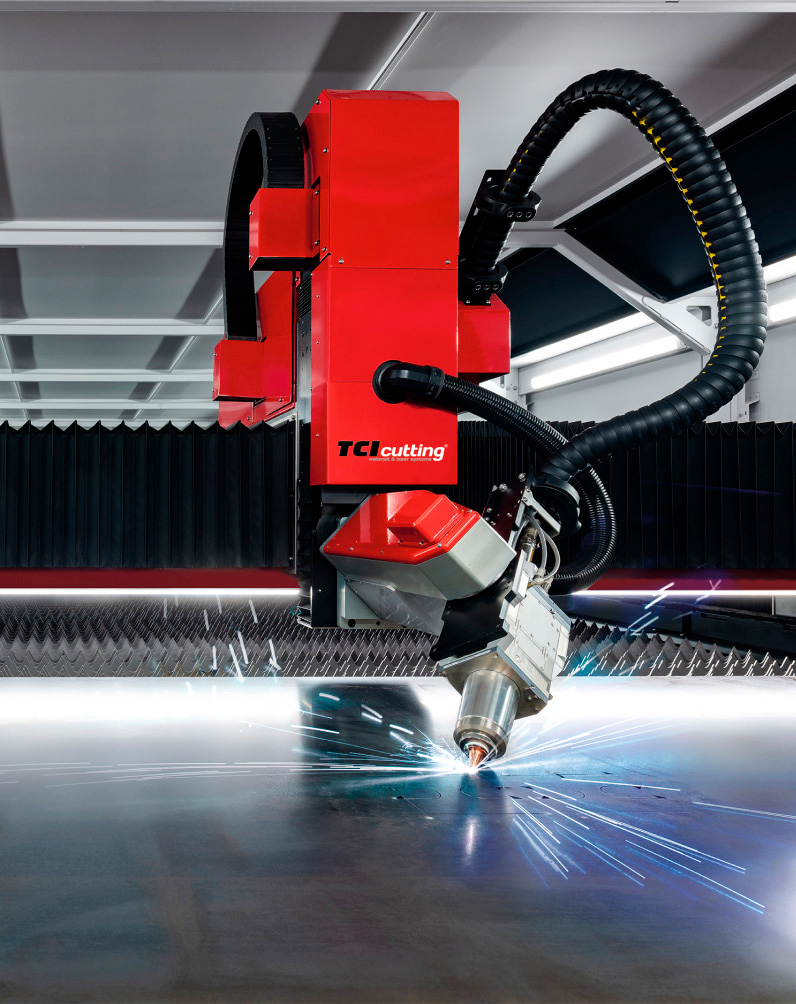

Regarding cutting with laser technology, our range of state-of-the-art machines responds to a multitude of demands. Our 2D and 2D1/2 Speeline Fiber ® laser cutting machine, for example, is the perfect machine for XXL formats. It is capable to cut large pieces with very specific properties and high resistance, something necessary for the defense and military sector.

3D cutting option

Infinite loop without rewind.

Modular

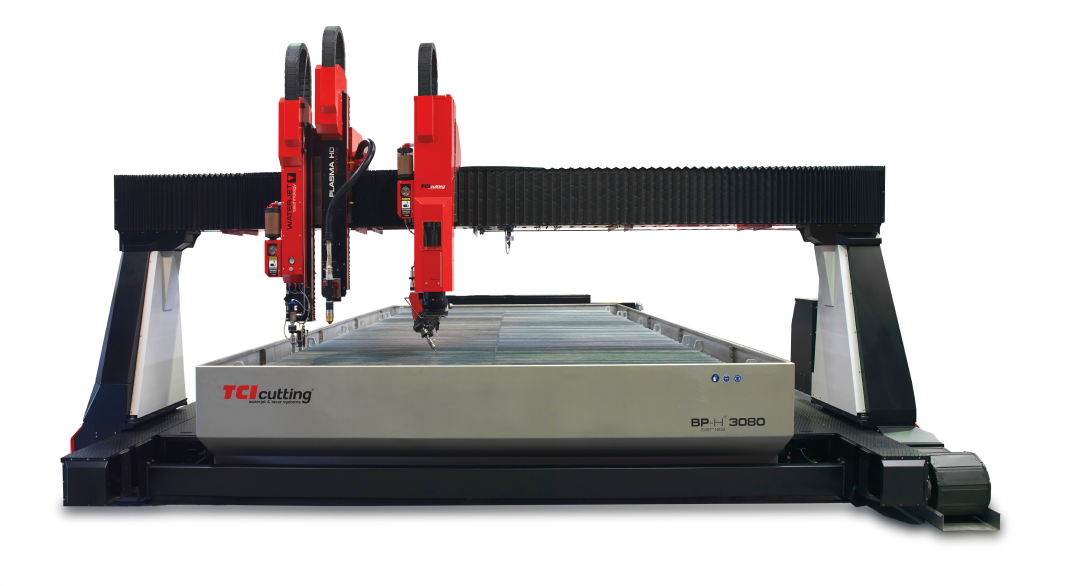

Expandable in length and scalable.

XXL size

Custom format

XXL size

Custom format

Multihead

Two laser heads option

2D1/2 cutting option

Bevel cut option

Accessibility

No waste of time

Easy drive

Simplicity and comfort

Flexibility

For multiple part changes

We advise you

Get advice on cutting machines for the defence sector with our specialised team.

SMART FACTORY

Intelligent

Automation

We create intelligent machines with autonomous decision making.

Tailor-made automation of production processes makes the production process more flexible, thus reducing costs by up to 60% and increasing productivity by 85%.

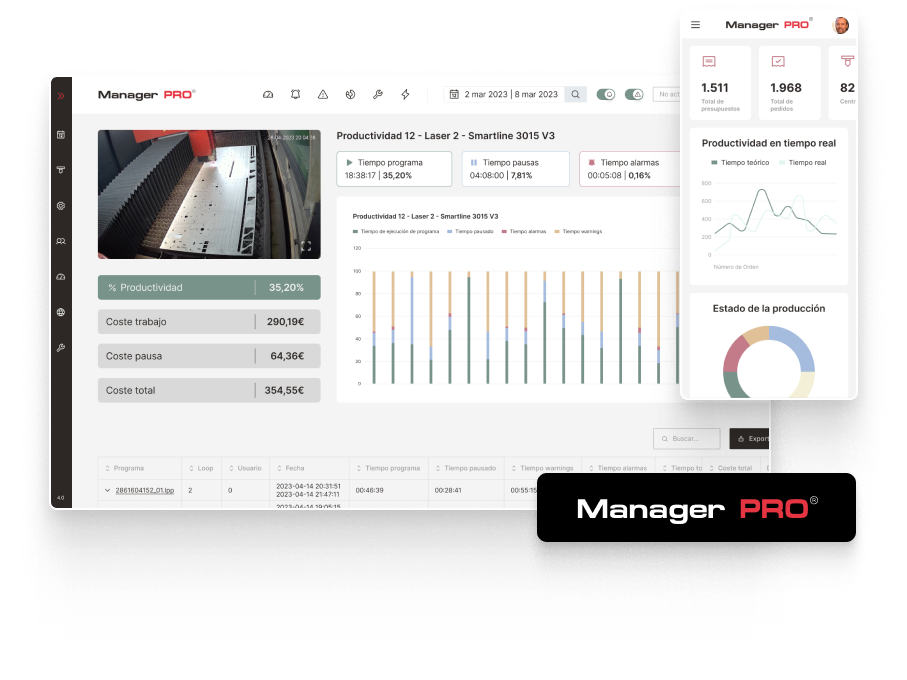

The brain of your smart factory

Production Management Software

Manager PRO® is the intelligent production management software and factory digitization. Manage your assets and optimize your production processes in real time from your computer, tablet or mobile.

+30%

Faster delivery times

+95%

Productivity increase

-80%

Reduction of administrative work

+55%

Logistics and production management capacity

BE PART OF THE FUTURE

Clients around the World