360º Technical Assistance for maximum efficiency and productivity

At TCI Cutting, we harness innovation to enhance our customers’ success. Our Technical Service (SAT) combines engineering expertise with the most advanced digital tools in diagnostics, monitoring and technical support.

We provide specialist service for our waterjet and laser cutting machines, automation systems and press brakes, with comprehensive solutions ranging from predictive maintenance to advanced training. Our approach prioritises incident prevention and immediate response, ensuring maximum operational efficiency for your equipment.

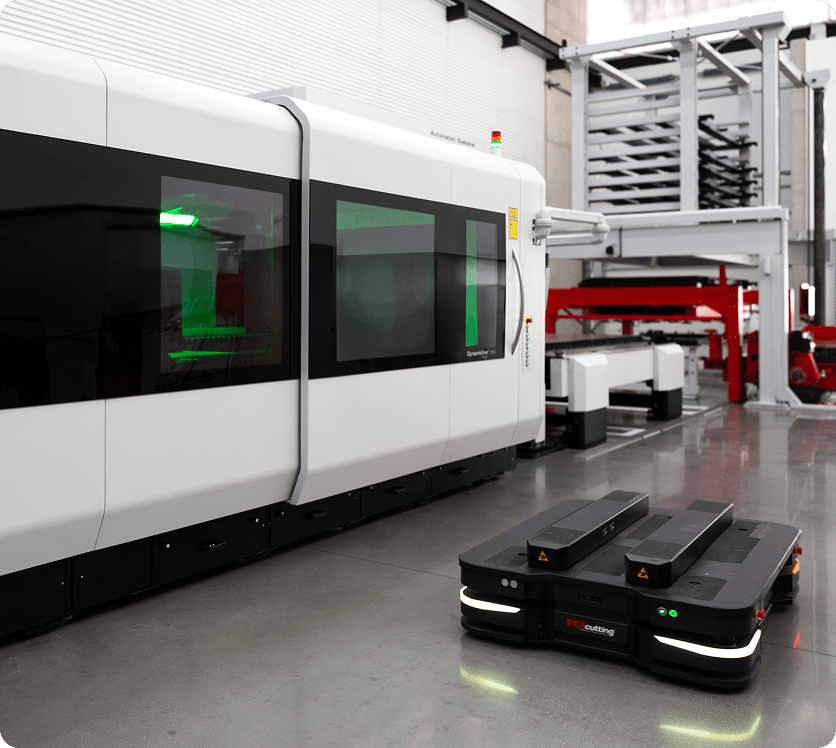

The goal is clear: maximise your machine availability, optimise processes and support you in the transition towards intelligent, autonomous production.

CONNECTIVITY AND PROACTIVE SUPPORT

Connected and predictive support

We integrate advanced technologies and data analytics to deliver predictive maintenance, identifying anomalies before they become real problems. This allows us to reduce unplanned downtime and optimise your machinery’s life cycle.

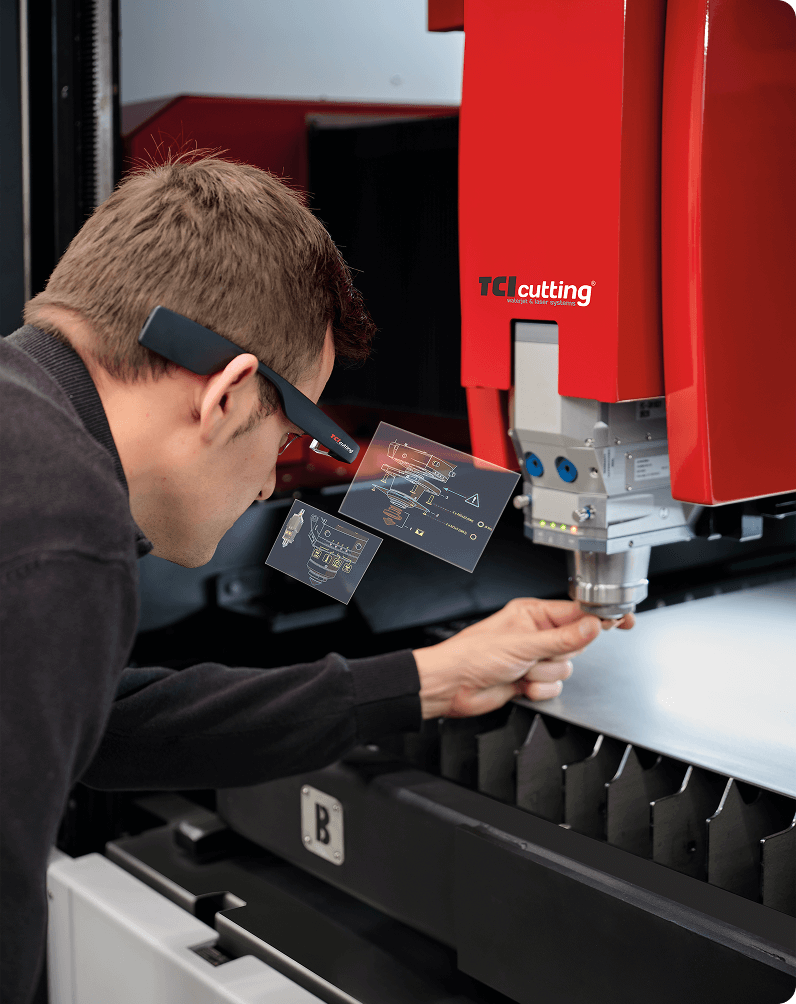

- Real-time technical assistance: our specialists resolve incidents via secure connection and online monitoring platforms.

- Predictive diagnostics: thanks to IoT integration and data analysis, we detect potential incidents, minimising unplanned downtime.

- Global availability: we provide support so that your production never stops, wherever you are.

DIGITAL ENGINEERING AND SPARE PARTS

Technology that ensures continuity and performance

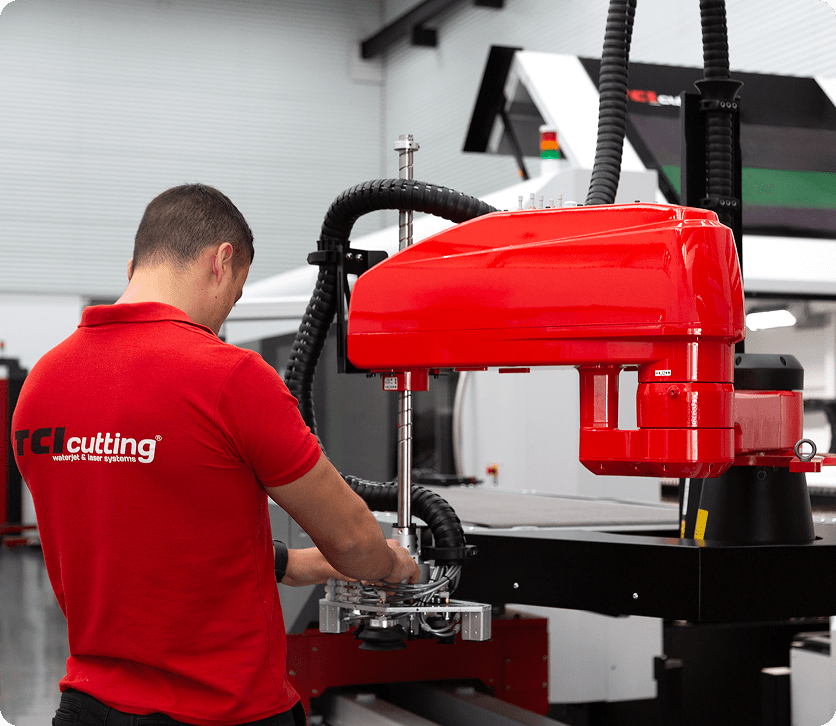

Our engineering team develops customised adaptation and automation projects, tailoring technology to your company’s specific needs. In this way, we not only solve incidents, we help your production evolve towards a more competitive and connected model.

A cutting-edge technical service requires equally advanced technical solutions. At TCI Cutting, every intervention also includes original spare parts of the highest quality, manufactured to guarantee maximum precision, durability and consistent performance.

- Custom engineering: we adapt your machinery to new requirements through scalable automation and connectivity solutions.

ADVANCED TRAINING AND ONGOING COMMITMENT

Knowledge HUB: empowering your team

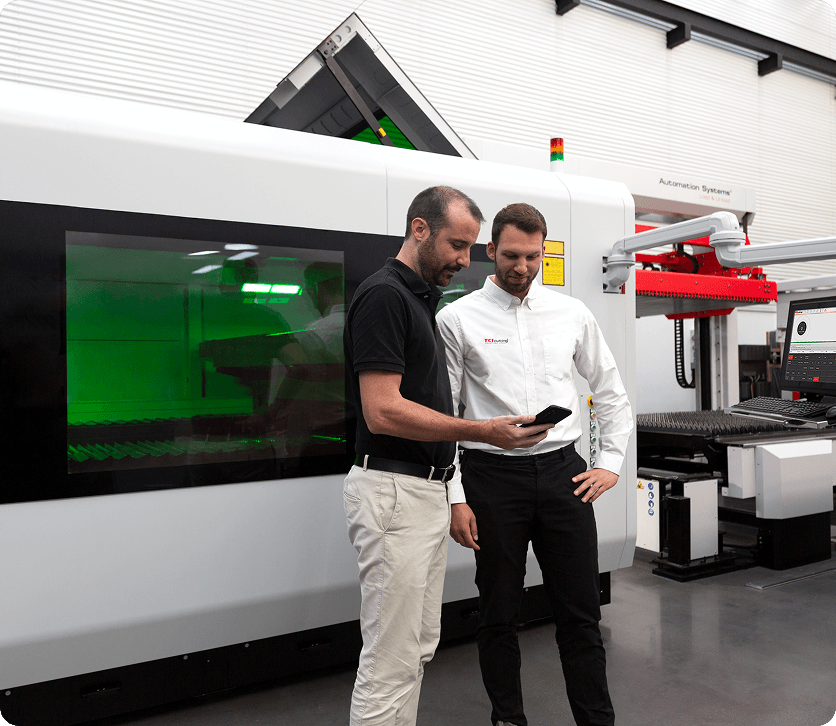

The best technology needs well-prepared teams. That is why at TCI Cutting we offer advanced training programmes for operators, technicians and production managers.

Our commitment does not end with the installation of a machine. We stay by your side throughout the entire life cycle of your cutting solution, evolving together towards the Smart Factory. At TCI Cutting, we believe in long-term relationships built on trust, innovation and excellence.

- Advanced technology training: theory-and-practice programmes focused on smart maintenance and process optimisation.

- Smart Factory commitment: much more than simple technical assistance, a technological partner that accompanies you on the path towards the Smart Factory.

We reduce downtime, we increase results

With TCI Cutting, your production enters the digital era: a smart, connected technical service always ready for the future.

Remote access and support

Download the TeamViewer application to access TCI Cutting’s remote support.