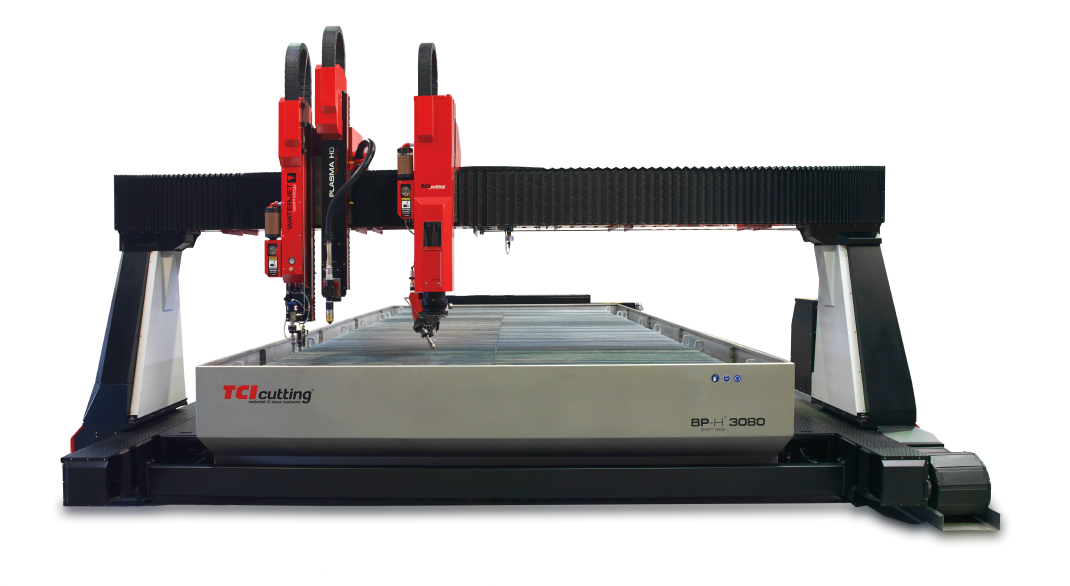

INDUSTRIAL CUTTING MACHINES

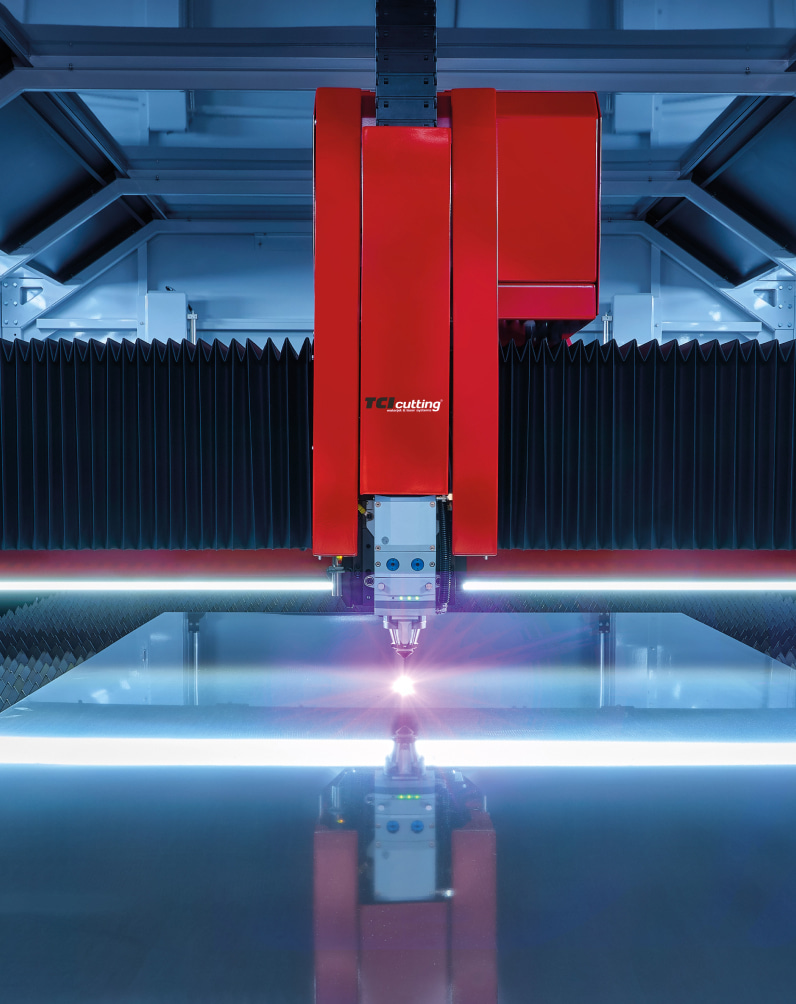

Laser cutting machines metal industry

ONE CLIENT, ONE SOLUTION.

Specific laser cutting machines for the metal sector.

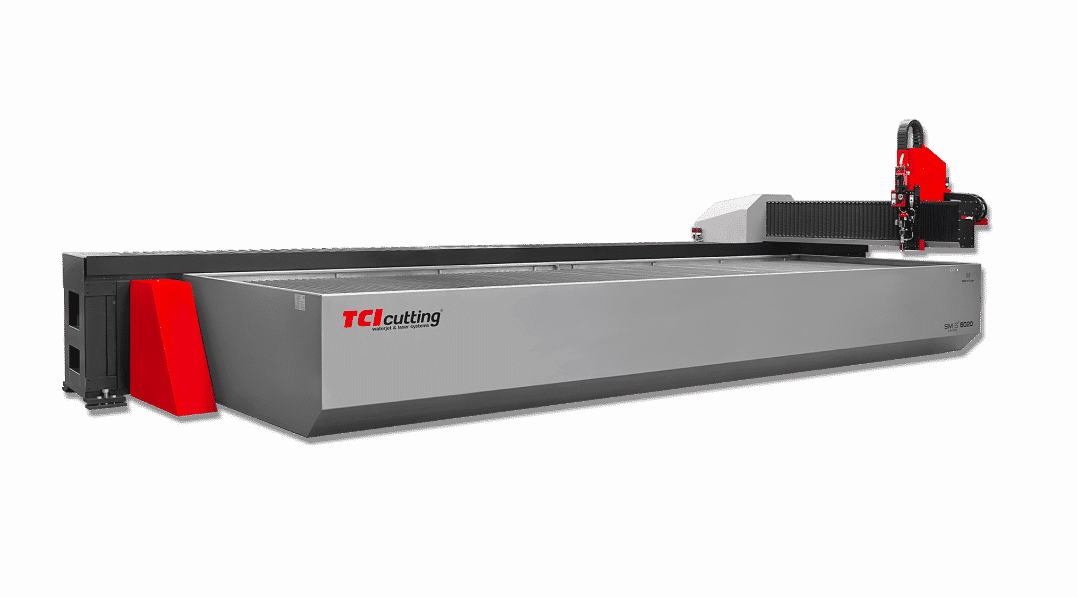

TCI Cutting’s laser cutting machines meet the specific cutting needs of sheet metal processing and industrial cutting companies in the metal sector thanks to a wide range of state-of-the-art cutting solutions of high-end technology. Laser cutting machines allow the cutting of multiple types of metal, such as steel, stainless steel, aluminum, brass and copper, among others, as well as cutting different thicknesses according to the client’s needs. There is also the possibility of developing tailor-made solutions adapted to the specific requirements of the sector and each company. One client, one solution. Thanks to innovative automated monitoring and traceability systems for parts a significant reduction in production costs is possible and the unit cost of the part is achieved.

TCI Cutting has, among others, high-end laser cutting machines such as the Smartline Fiber®, compact and flexible 2D cutting for different materials and cuts, the Smarttube Fiber® machine for high-precision cutting of metal tubes and profiles (2D or 3D) and the latest generation Dynamicline Fiber® machine, a 2D cutting solution with high productivity and high cutting speed. These solutions cover the cutting needs of the metal sector and the transformation of sheet metal industry, optimizing production flows.

Cutting machines can be optimized through tailor-made automation solutions and intelligent production management software for autonomous and strategic decision making.

Accessibility

Easy use

Flexibility

For multiple changes of pieces

Compact design

Ergonomics. Space saving

High Productivity

Max acceleration 4G

High Accuracy

Direct measurement and linear motors

Energy Saving

Very reduced electric consumption

High productivity

Multiple loaders for profiles and tubes

Profiles and Tubes Cutting

Open or closed profiles

Customization

Semi-Automatic or automatic loading. 2D/3D cutting heads

We advise you

Get advice on cutting machines for the metal sector from our specialised team.

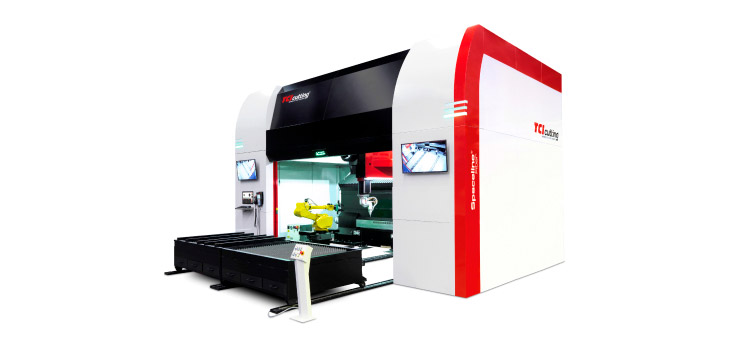

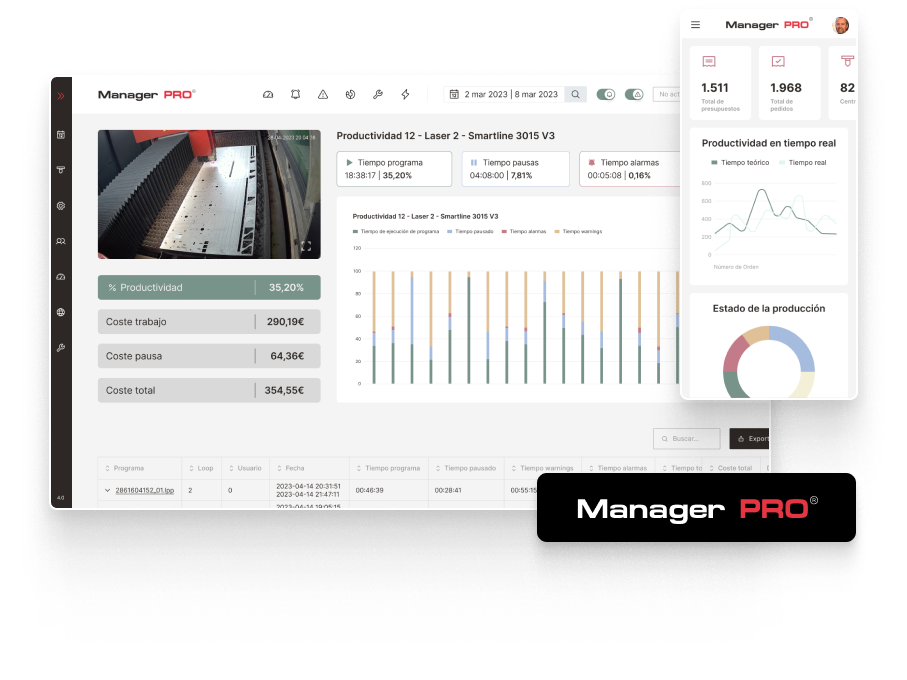

SMART FACTORY

Intelligent

Automation

We create intelligent machines with autonomous decision making.

Customized automation of production processes makes the production process more flexible, thus reducing costs by up to 60% and increasing productivity by 85% .

PROCESSES IN REAL TIME

Production management software

TCI Cutting is a market expert in intelligent softwares for production optimation to generate intelligent communication systems machine-machine and man-machine in a complete automation of factories environment.

Our intelligent softwares offer strategic information in real time to reduce costs and achieve an efficient and complete interconnection.

+30%

Faster delivery times

+95%

Productivity increase

-80%

Reduction of administrative work

+55%

Logistics and production management capacity

BE PART OF THE FUTURE

Clients around the World