AUTOMATION

Increased productivity,

speed and customisation

Intelligent automation as part of the new era with direct impact on the production process.

Greater productivity, speed and customization. Factories interconnected at a digital level thanks to intelligent production management software for autonomous and strategic decision making (TCI Manager). The future of the cutting sector or the cutting sector of the future?

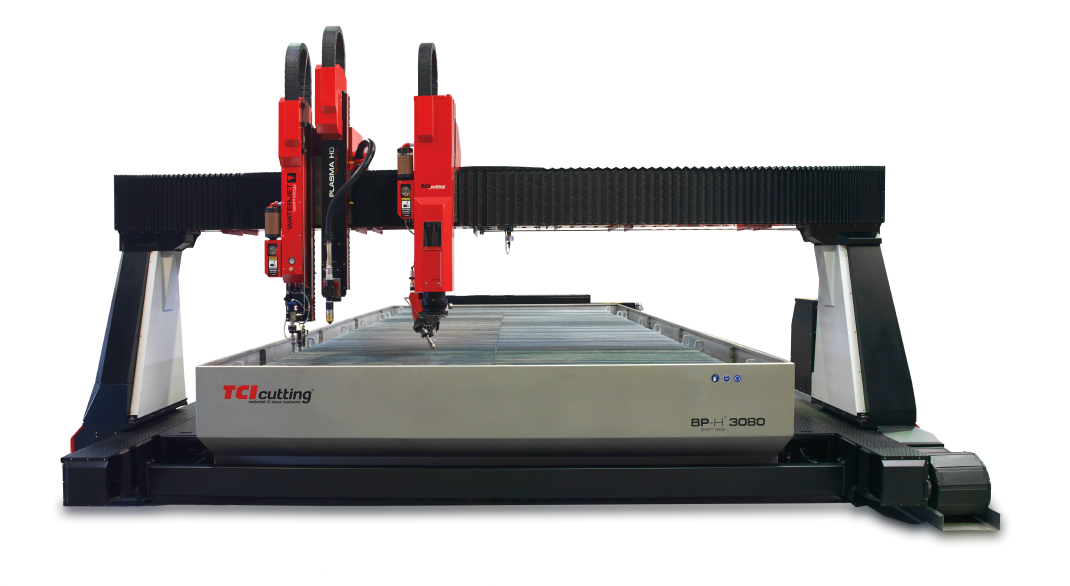

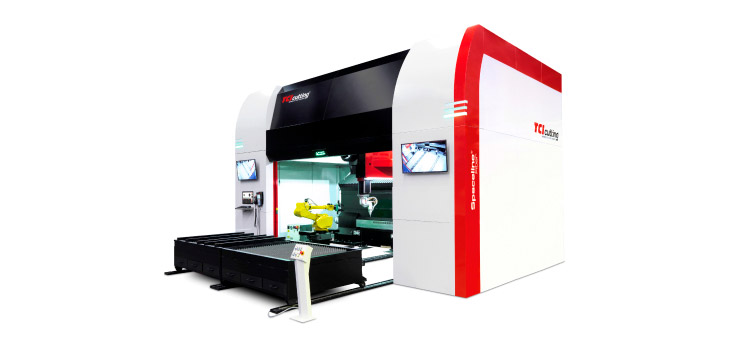

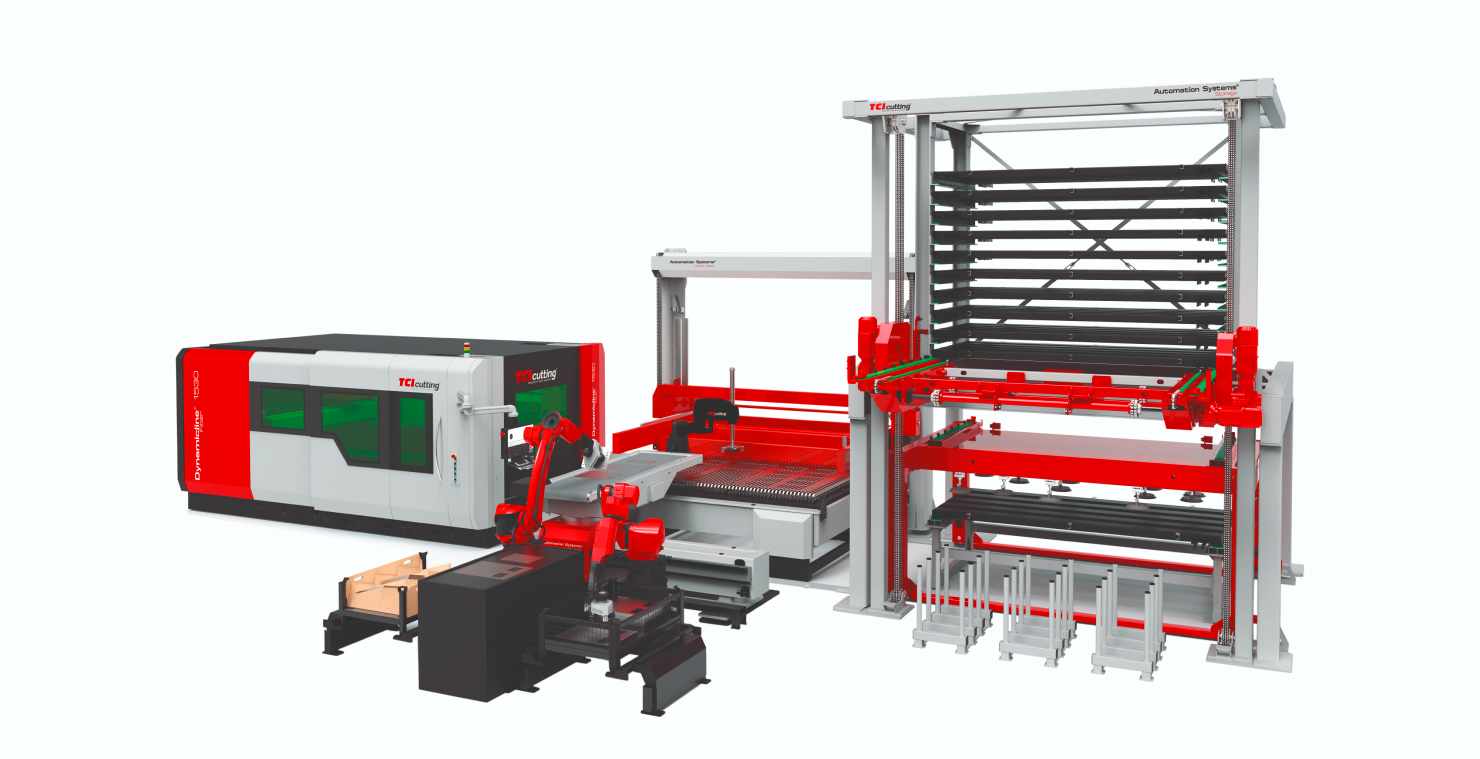

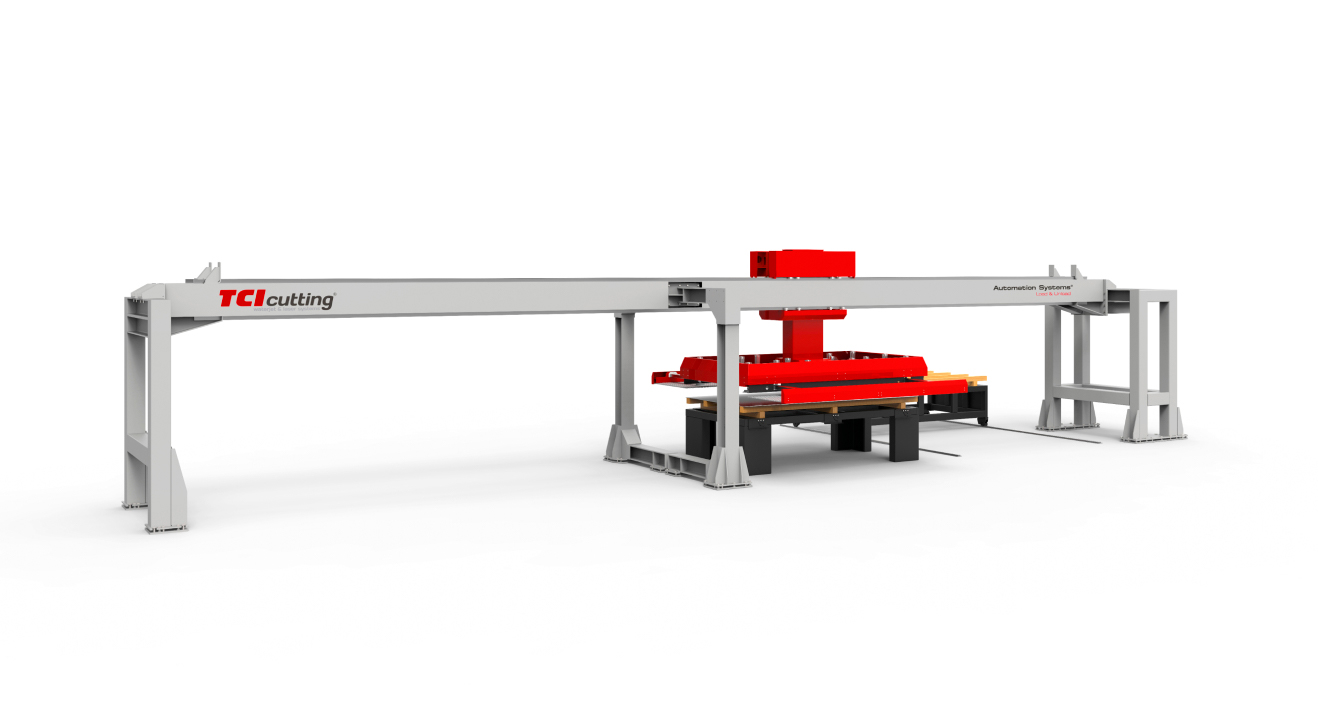

Smart production island

Automation Systems®

Smart production island inside cutting factories.

High-end sheet metal cutting with simultaneous loading and unloading, automated storage and parts smart sorting. Parts can be palletized in boxes, sent to robots or distributed by self-guided vehicles, among others.

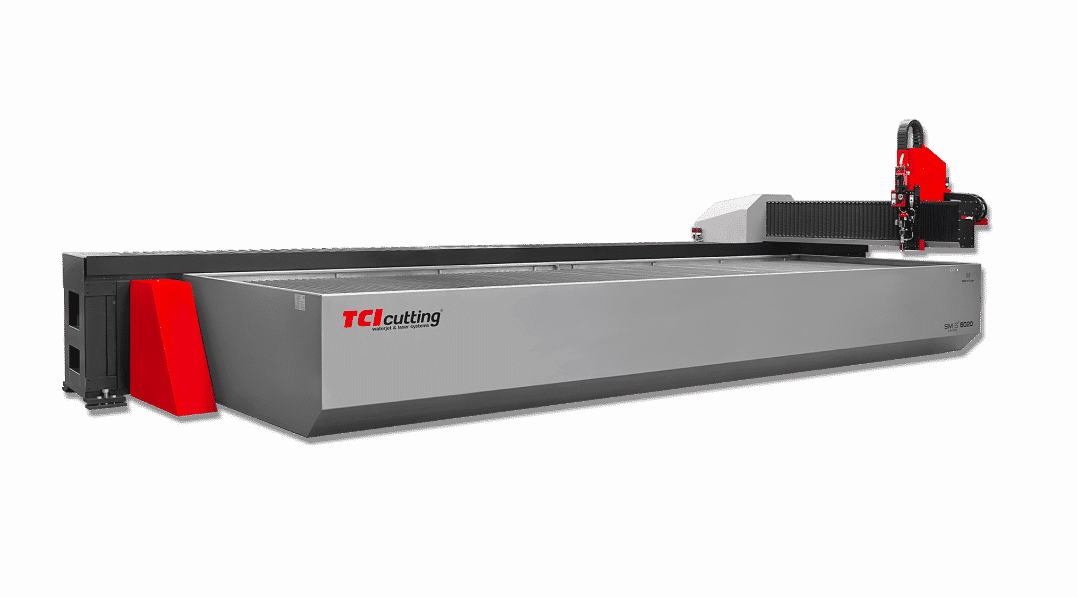

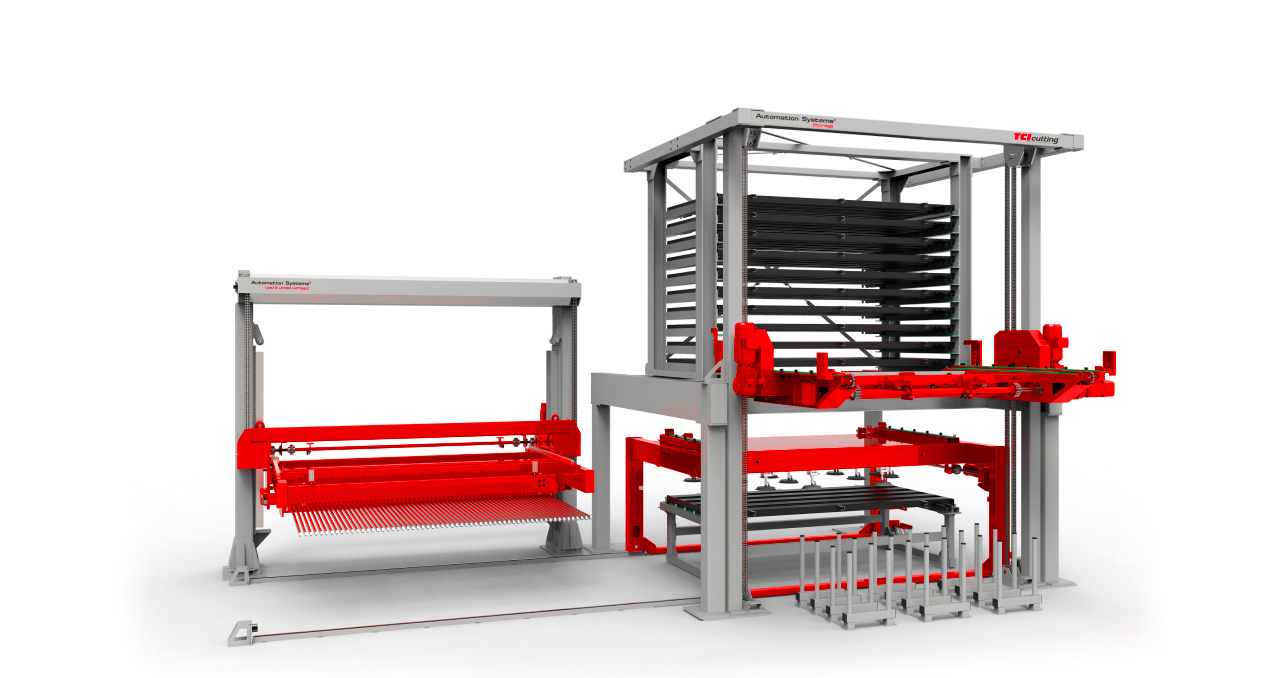

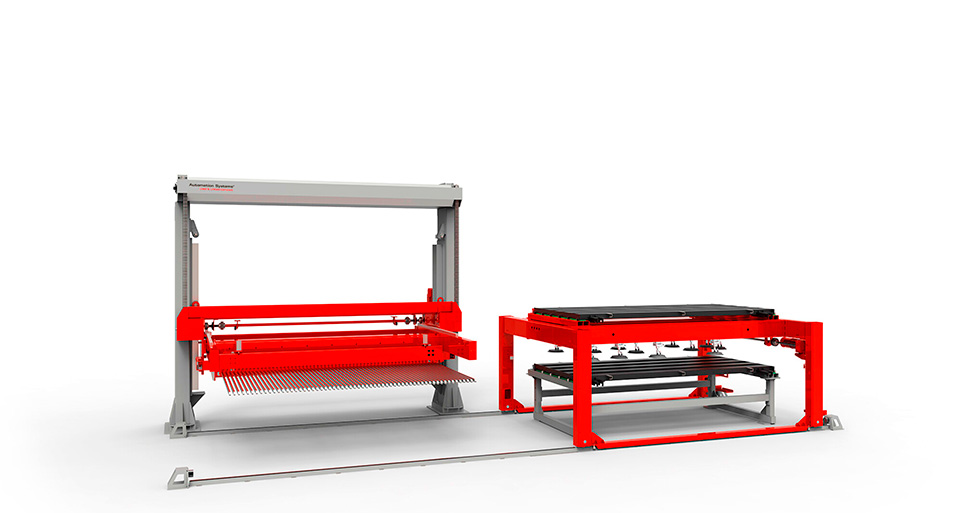

Loading & unloading with Storage

Automation Systems®

Very compact system with integral automation.

Simultaneous loading and unloading, and storage. Height and quantity of trays tailored according to customer needs. Possibility of adding a SingleTower or DoubleTower at the beginning or as an additional module later. Flexibility in loading and unloading positions in real time. Possibility of including trays of more height for unloading. Loading and unloading in the same movement with a very short cycle. Free accessibility to the machine table for loading/unloading.

Automation Systems®

The solutions included range from simple handling to fully automated and modular operation. Fast processing of the cutting cycle, since automatic loading and unloading reduces cycle times . Possibility of automated storage as an additional module afterwards. Improves both job safety and process safety.

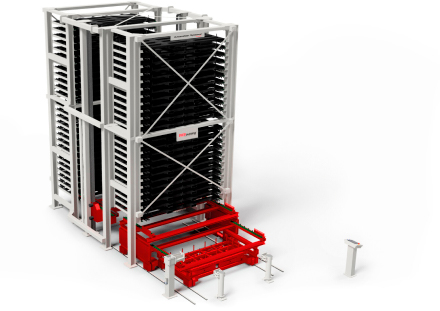

Automation Systems®

TCI Cutting has a complete range of automation towers for laser. TCI Tower is designed to help improve productivity and increase profits, while reducing delivery times and costs.

This automated loading and unloading system uses vertical space in factory to improve material handling and at the same time time offers flexibility to small batch production of different materials or longer production processes.

Automation Systems®

- Full integration automatic function.

- Material weighing and stock control.

- Removable trays for logistics within the company and supply other production stations.

- Height and quantity of trays made to measure for each project.

- Flexibility in loading and unloading positions in real time.

- Possibility of including trays with more height for unloading.

- Possibility of including the double table to reduce the loading/unloading cycle.

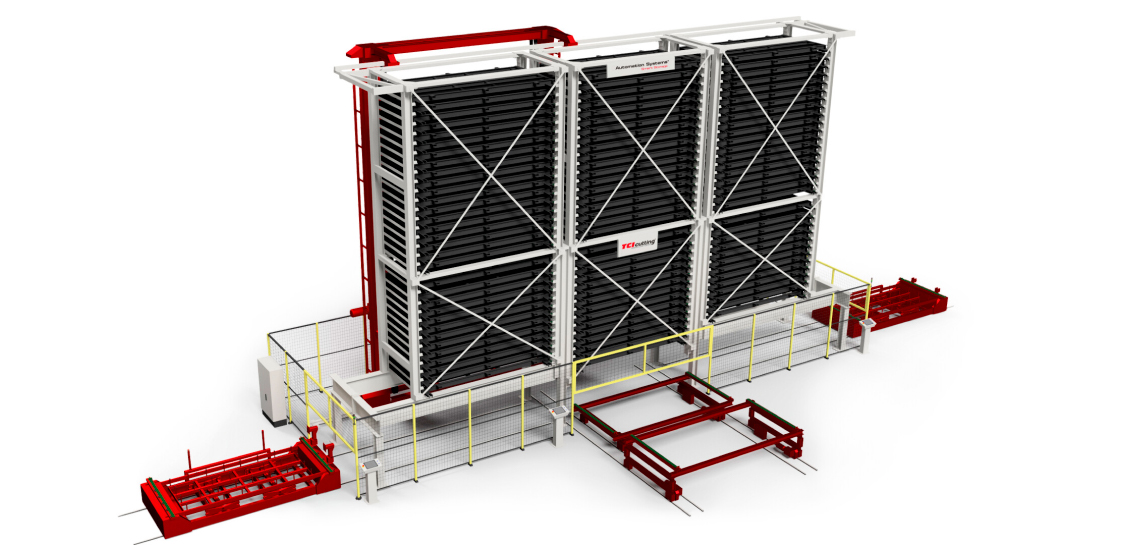

Automation Systems®

- Full integration automatic function.

- Material weighing and stock control.

- Removable trays for logistics within the company and supply other production stations.

- Height and quantity of trays made to measure for each project.

- Flexibility in loading and unloading positions in real time.

- Possibility of including trays with more height for unloading.

- Possibility of including the double table to reduce the loading/unloading cycle.

- Possibility of adding station to load/unload independent material.

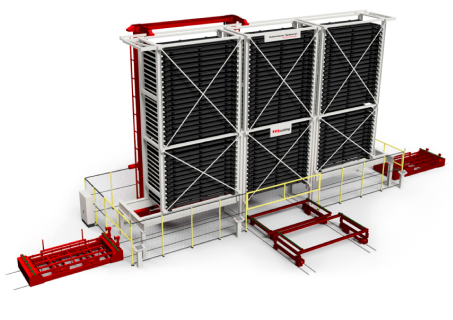

Automation Systems®

- Full integration automatic function.

- Material weighing and stock control.

- Removable trays for logistics within the company and supply other production stations.

- Height and quantity of trays made to measure for each project.

- Flexibility in loading and unloading positions in real time.

- Possibility of including trays with more height for unloading.

- Possibility of including the double table to reduce the loading/unloading cycle.

- Possibility of adding station to load/unload independent material.

- Possibility of adding several machines and supplying automatically.

Loading & unloading

Automation Systems®

The solutions included range from simple handling to fully automated and modular operation. Fast processing of the cutting cycle, since automatic loading and unloading reduces cycle times. Possibility of automated storage as an additional module afterwards. Improves both job safety and process safety.

Automation Systems®

Very compact system.

Automated simultaneous loading and unloading system. Material weighing and stock control. Material thickness measurement. Possibility of integrating an automated storage module as an additional module afterwards. Flexibility in loading and unloading positions in real time. Loading and unloading in the same movement with a very short cycle. Free accessibility to the machine table for direct loading/unloading.

Automated loading

Automation Systems®

Intelligent solutions for loading in laser cutting facilities.

Fast order processing, since automatic loading reduces preparation times. Considerably greater use of machinery with only a slight increase in investment. Access to the production of parts with little manual work. Flexible use.

Automation Systems®

Accredited solution for the efficient handling of metal sheets, with which the loading of material on the laser cutting tables becomes a simple process within the workflow.

- Nominal dimension of the sheet: 3000 x 1500 mm

- Thickness of the load plates 0.8 – 25 mm

- Maximum weight of the sheet metal plate 750 kg

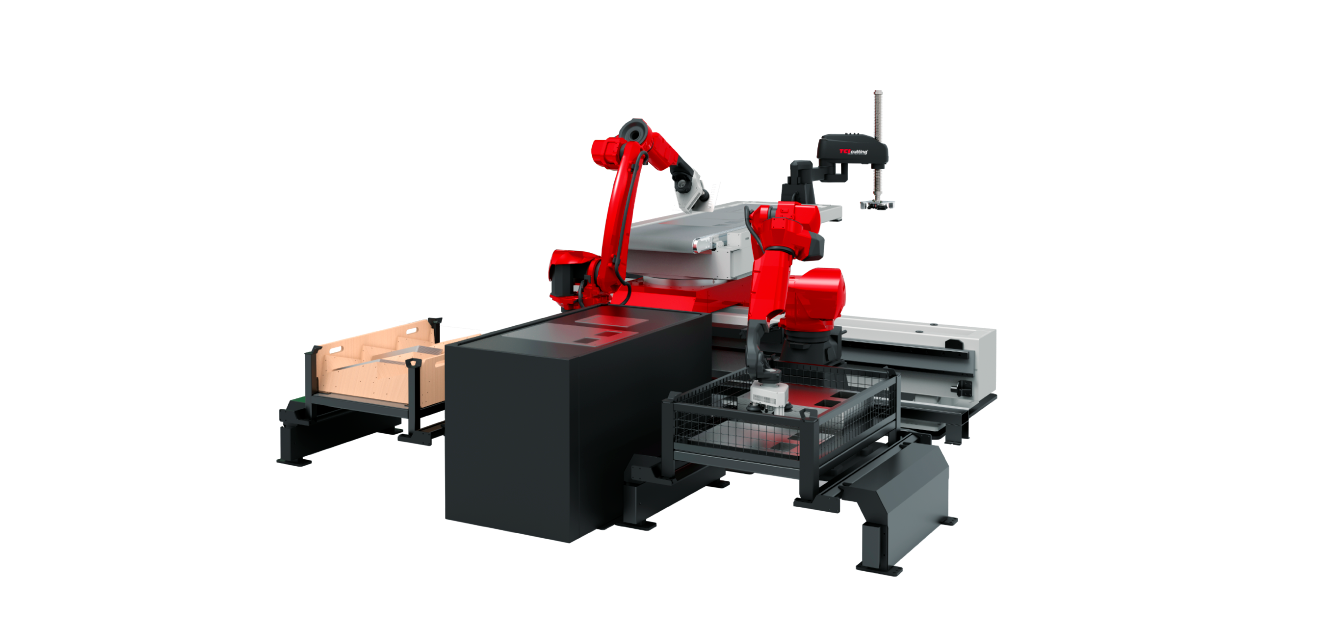

Smart sorting

Automation Systems®

TCI Cutting’s smart sorting system and automated palletizing system.

Parts smart sorting and automated palletizing. Subsequent distribution using AMR (Autonomous Mobile Robot) among the different processes complementary to cutting. Pieces can be classified in the order commanded by Manager PRO® or in the order indicated by the cutting operator. This solution guarantees optimal planning, order and control within the factory, as well as more efficiency of time and business resources.

Benefits

Why

TCI Cutting

Autonomous decision making.

BE PART OF THE FUTURE

Clients around the World

Download data sheet