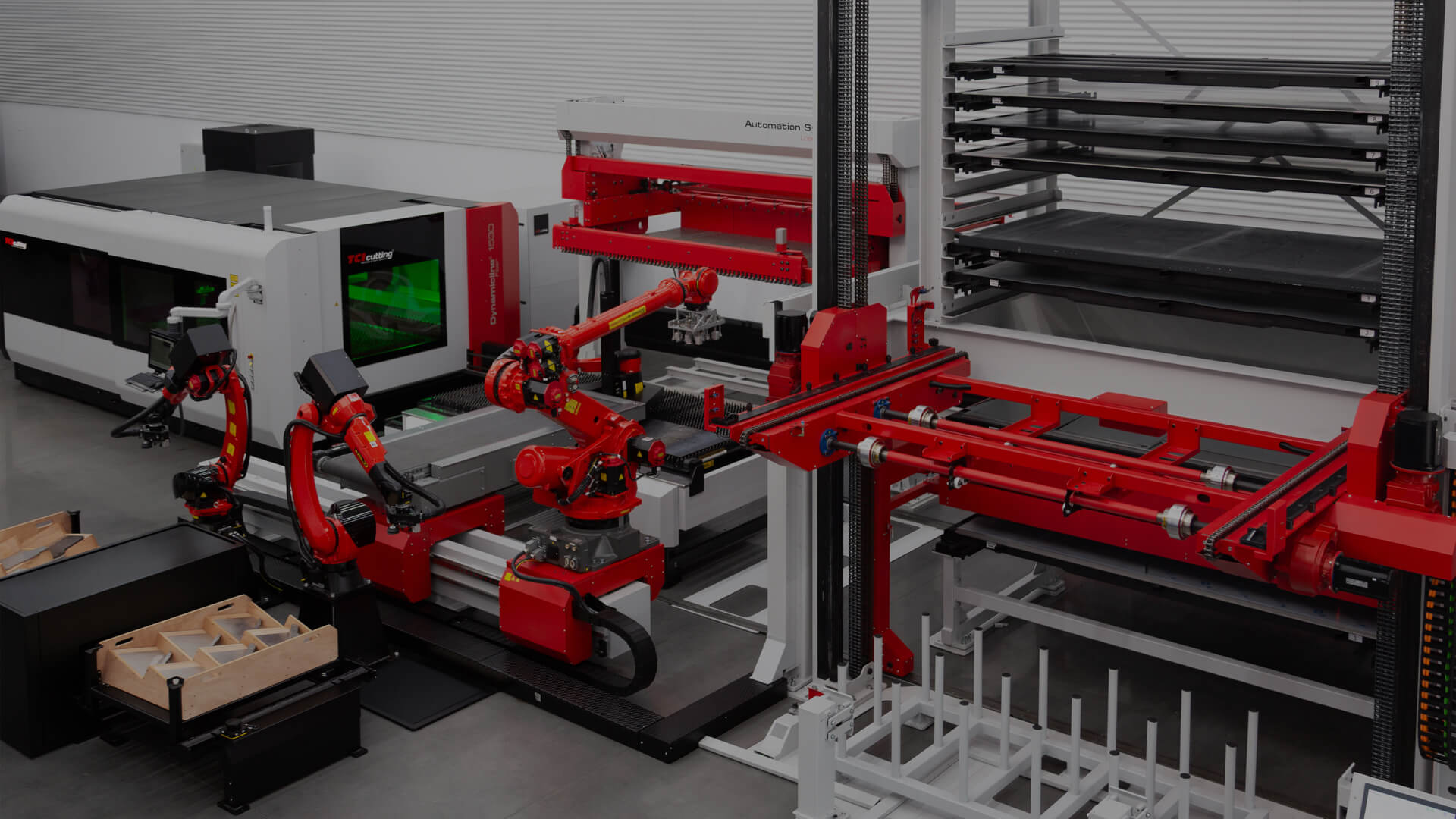

Under its MAS Concept®, TCI Cutting will showcase at the Bilbao exhibition its production cell composed of the Dynamicline Fiber® laser cutting machine, the intelligent CLS loading and unloading automation system, and the patented Smart Sorting® solution designed to accelerate part sorting and palletizing. A flexible, high-speed, AI-powered system created to multiply companies’ productivity.

As a manufacturer of fully autonomous 2D laser cutting machinery, TCI Cutting will take part in the 33rd edition of BIEMH with a demonstration clearly focused on productivity: its highly autonomous cutting cell combining the Dynamicline Fiber® laser cutting machine, CLS loading and unloading automation, and the Automation Systems Smart Sorting® solution, designed to take sorting and palletizing to a new level of speed, flexibility and efficiency. With a multi-tool option, the system guarantees total versatility, handling parts ranging from 25 × 25 mm to 1,500 × 910 mm, with a maximum weight of 50 kg.

The Valencia-based company will present its Automation Systems Smart Sorting® solution, patented by TCI Cutting, which automates part unloading, sorting and palletizing through Artificial Intelligence (AI), comprehensively accelerating and optimizing post-cutting processes while increasing the overall efficiency and autonomy of the production cell.

TCI Cutting has developed a vision focused on integrated solutions that combine high-precision machinery, advanced automation, robotic integration and production management software, with a clear objective: to provide companies with tools that enhance their competitiveness in the global market.

Smart Sorting: AI, speed, flexibility and easy configuration to accelerate production flow

The Automation Systems Smart Sorting® sorting and palletizing solution is capable of automatically calculating the optimal extraction formula from the cutting table. This information is sent to the SCARA robot, which executes the movement in real time, with self-learning and continuous improvement.

The system stands out for performing part extraction simultaneously with automated palletizing, reducing non-productive times and rapidly accelerating production flow. Subsequently, pallets can be transported by autonomous mobile robots (AMRs) to downstream processes, also automating internal plant logistics.

One of its key strengths is ease of configuration, thanks to TCI Sorter® software, developed by TCI Cutting. This tool allows quick and flexible adjustment of robot operations to adapt to different part types, stacking criteria and priorities with extreme ease. In addition, the software incorporates AI-based functionalities that facilitate criteria definition and help improve process consistency based on production data.

24/7 productivity and scalable automation with Dynamicline Fiber®, Automation Systems Load & Unload® and Smart Sorting

As a core element of the production cell, Dynamicline Fiber® is a 2D laser cutting machine specifically designed for high-productivity environments and is complemented by the Automation Systems Load & Unload® system, which automates material handling and loading/unloading with precision and safety. This automation can also be expanded with one or more smart storage systems, adding automated intelligent storage capacity to increase autonomy and adapt the system to each plant’s production requirements.

MAS Concept®: an interconnected and digitalized ecosystem for data-driven production

TCI Cutting’s MAS Concept® (Machinery, Automation and Software) approach promotes full integration of the production chain: highly autonomous intelligent cutting machines, advanced automation and production software within a connected, digitalized and scalable ecosystem.

Within this vision, Manager PRO® plays a key role as proprietary production software: it enables communication with the laser cutting machine while strengthening monitoring, traceability, analytics and data centralization of the production process from any device. It also incorporates a business intelligence module to support real-time decision-making, further enhanced by AI integration.

According to Emilio Mateu Sentamans, CEO – Executive Director of TCI Cutting, “Our technological solutions aim to guide factories towards a highly automated and digitalized smart factory model, with AI and IoT technology, fully data-driven management and a strong focus on increasing productivity, efficiency and reducing operating costs.”