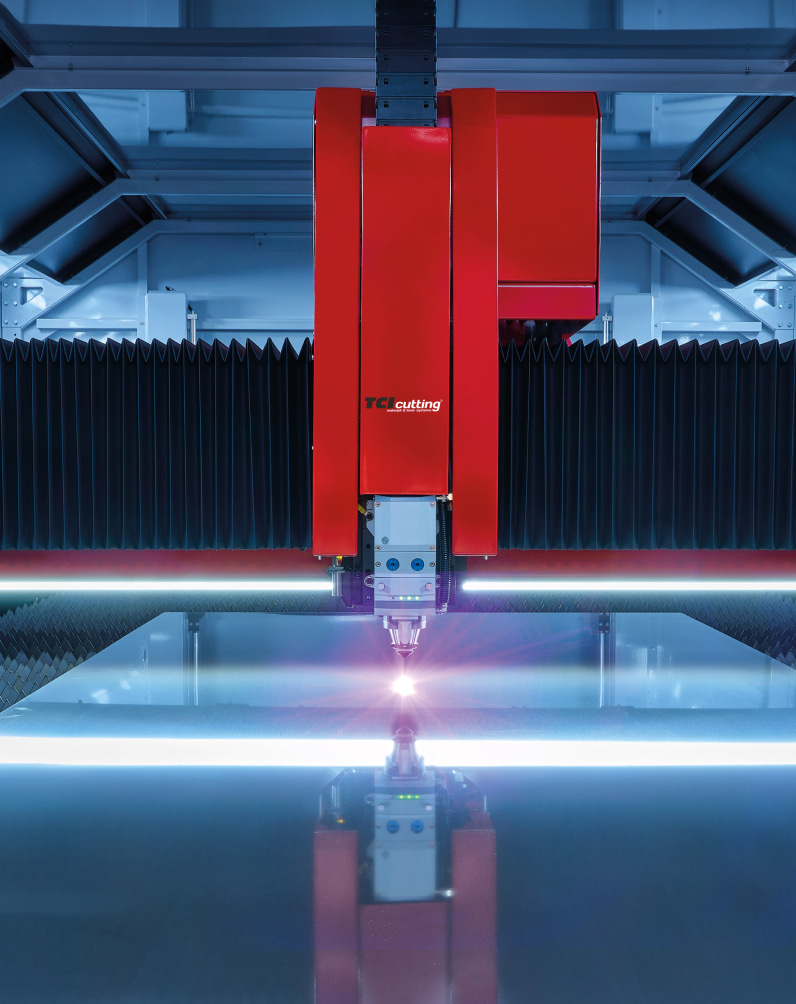

Fiber Laser Cutting Machines

LASER CUTTING

Cutting-edge technology

Our reason for being, innovation and utmost technological development to satisfy needs of companies dedicated to industrial cutting activities, in a wide range of materials. In TCI Cutting we want to offer our customers the laser cutting machine that best meets their concrete needs.

Fiber cutting systems are the most innovative laser cutting development of the market. We also maintain the production of the CO2 laser cutting machines due to their specific aplications.

2D FIBER CUTTING

2D Fiber Laser

Cutting Machines

ACCESSIBILITY / FLEXIBILITY

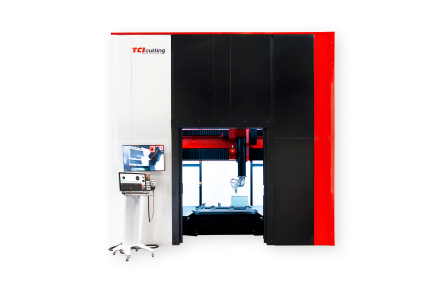

Smartline Fiber®

The most flexible and accessible 2D fiber laser cutting system on the market.

HIGH PRODUCTIVITY

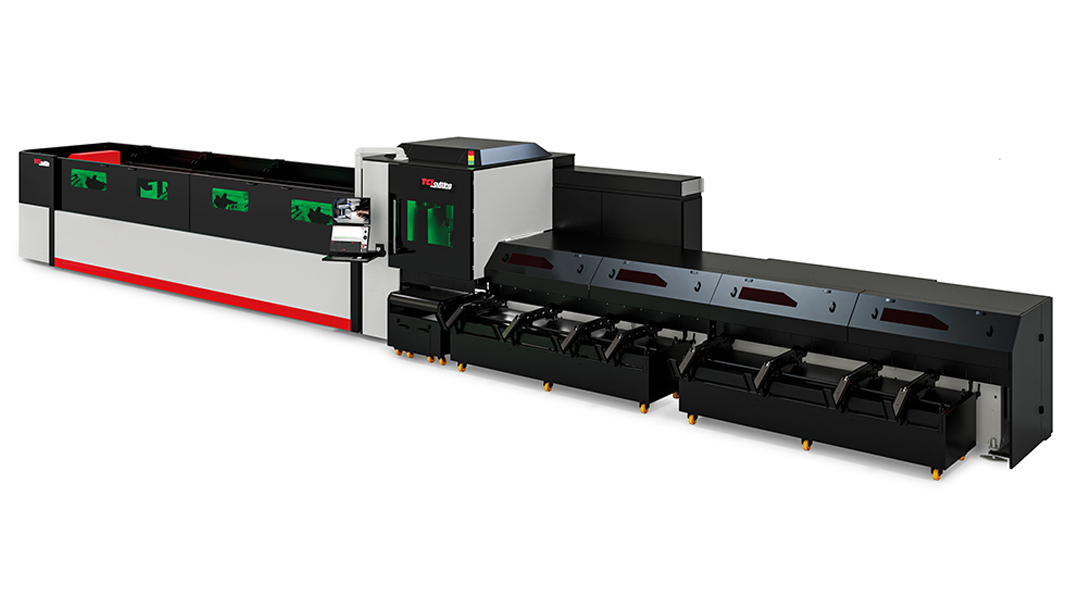

Dynamicline Fiber®

The Dynamicline Fiber® is pure productivity for large series and volumes, without losing sight of electrical and production efficiency.

XXL FORMAT

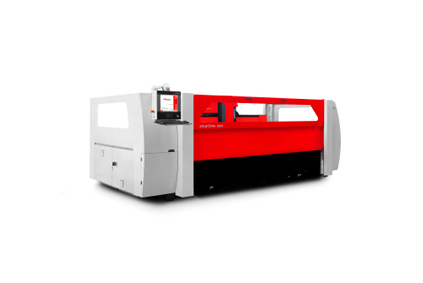

SpeedLine Fiber®

2D cutting and option of 2D1/2 and multihead for simultaneous cutting jobs, automatically adjustable in distance.

TUBE FIBER CUTTING

Tube Fiber Laser

Cutting Machines

PROFILES AND TUBES CUTTING

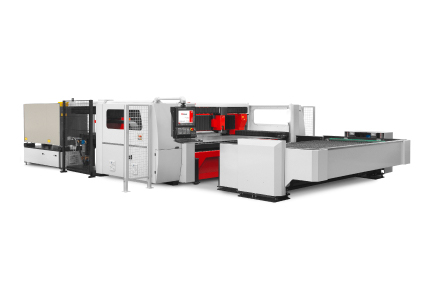

Smarttube Fiber®

The laser fiber technology arrives to profiles and tubes cutting production.

2D CO2 CUTTING

2D CO2 Laser

Cutting Machines

COMPACT CO2 SOLUTION

Smartline L Power®

CO2 laser series with sealed resonators and a power ranging from 100W to 600 W.

We advise you

Get advice on Laser Cutting Machines with our specialized team.

TCI CUTTING