AUTOMATION

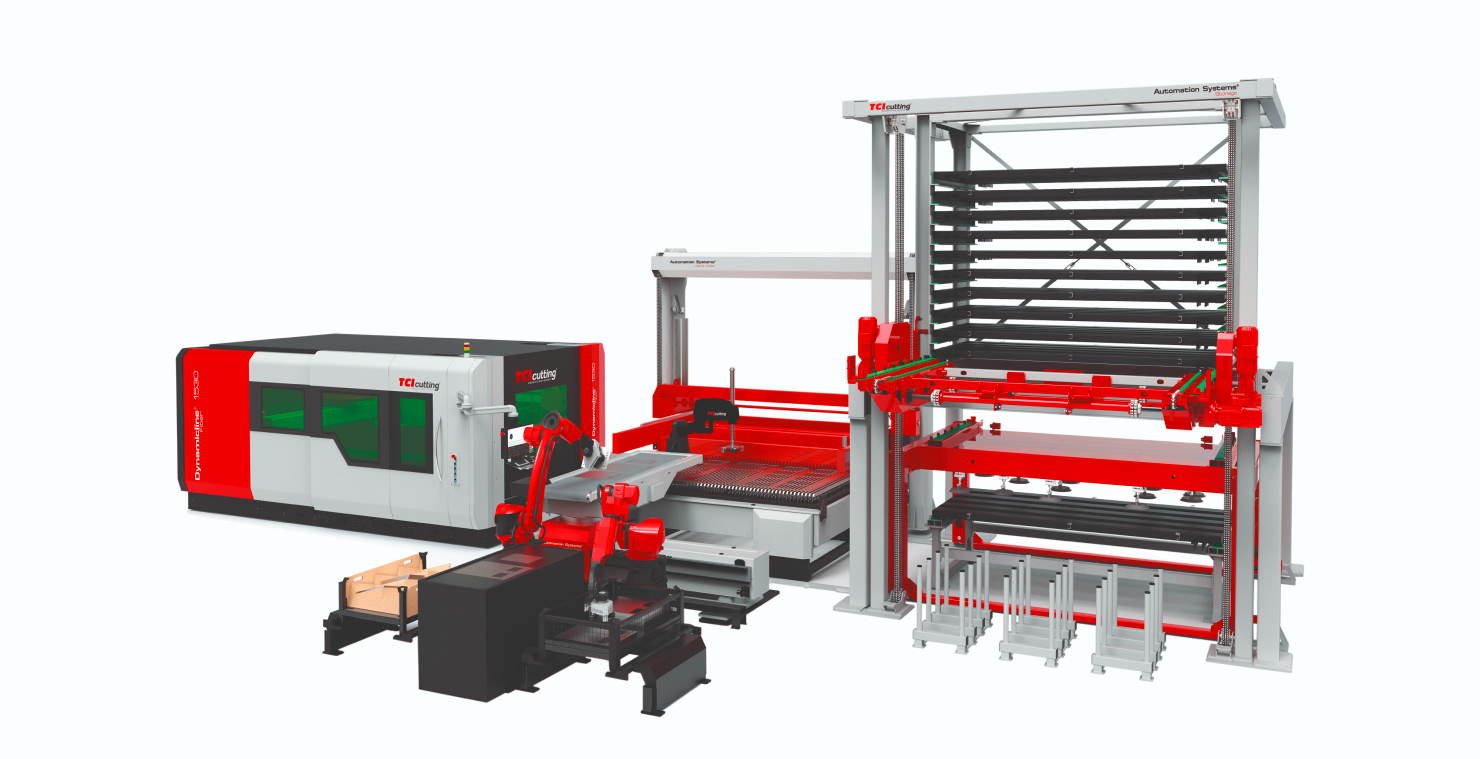

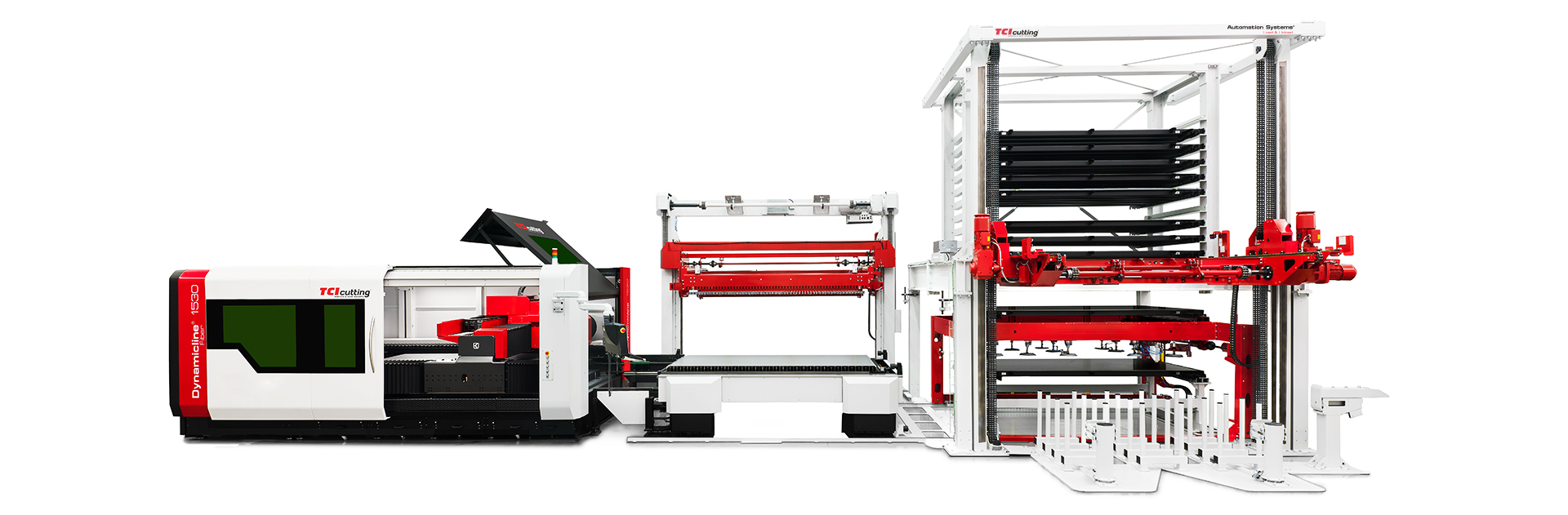

2D Laser cutting

TCI Cutting’s 2D laser cutting machines can integrate tailor-made and scalable smart automation solutions. Automation of loading, unloading and storage can be be accompanied by parts smart sorting system – Automation Systems Smart Sorting®, and subsequent automated palletizing. The parts can be transported by an AMR (Autonomous Mobile Robot) that connects smart productive islands – Automation Systems Smart Cell®.

This enables a fast, top-quality response to customers in an increasingly automated digital environment. Cutting factories that are increasingly intelligent and adapted to today’s highly demanding and changing market.

AUTOMATION

3D Laser cutting

Fully robotic system that converts hitherto complex 3D cuts into highly simple cuts. Multi-angle cutting programs. Repositioning of parts with robot.

AUTOMATION

Tube laser cutting

Automate your cutting of tubes and profiles using fiber laser technology. Automatic or semi-automatic loading and automated unloading. 2D or 3D head. New business opportunities, multiple application sectors.

AUTOMATION

Bending process

Automation thanks to Automation Systems Bending Robot®. Intuitive and easy-to-use HMI Bending software. High precision and customization.

We advise you

Do you want to automate your production and be more competitive?

BE PART OF THE FUTURE

Clients around the World