INDUSTRIAL CUTTING MACHINES

Cutting machines for aeronautics / aerospace

Waterjet and laser cutting machines for the aeronautical sector.

The Smartline Fiber cutting system offers the perfect, flexible, high-precision cutting for companies with changing needs, with multiple automation solutions to meet all types of industry demands.

TCI Cutting’s cutting machines offer industrial cutting solutions adapted to the needs of the aeronautical sector. Machines of different cutting technologies, laser or waterjet, that cover the cutting of multiple materials commonly used in the aeronautical industry, composite materials, technical fibers such as carbon fiber or glass, resins, polymers and all kinds of metals.

TCI Cutting’s cutting machines cover different volumes, formats and cutting needs, with modular and flexible systems and XXL cutting machines.

TCI Cutting’s waterjet cutting machines provide an industrial cutting solution for aeronautical companies. BP-C waterjet cutting machines, flexible and accessible, handle 2D and 2D1/2 cuts covering all the standard needs of the sector. For large volumes BP-H waterjet modular machines are able to cut large formats with the possibility of 5-axis and 2D, 2D1/2 and 3D cutting.The Smartline Fiber cutting system offers the perfect, flexible, high-precision cutting for companies with changing needs, with multiple automation solutions to meet all types of industry demands.

3D cutting option

Infinite rotation without rewinding.

Modular

Expandable in length and scalable in resources. Clean and quiet working conditions. Customisable.

Size XXL

Tailor-made format.

Accessibility

Easy to use

Flexibility

For multiple part changes

Compact design

Ergonomics. Space-saving

Accessibility

No time wasted

Easy handling

Simplicity and comfort

Flexibility

For multiple part changes

We advise you

Get advice on cutting machines for the aeronautical sector from our specialised team.

SMART FACTORY

Intelligent

Automation

We create intelligent machines with autonomous decision making.

Tailor-made automation of production processes makes the production process more flexible, thus reducing costs by up to 60% and increasing productivity by 85%.

The brain of your smart factory

Production Management Software

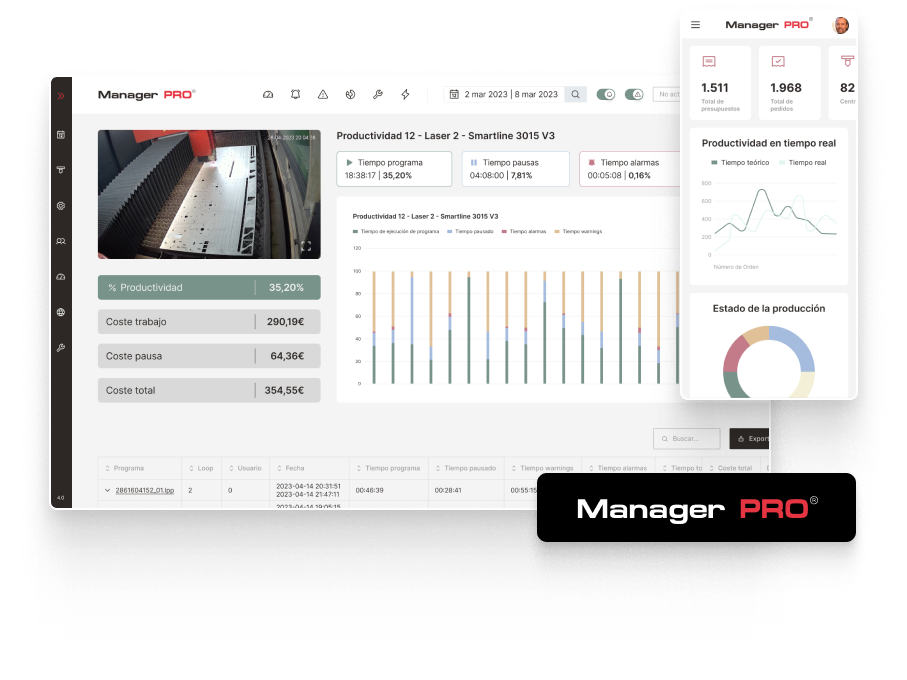

Manager PRO® is the intelligent production management software and factory digitization. Manage your assets and optimize your production processes in real time from your computer, tablet or mobile.

+30%

Faster delivery times

+95%

Productivity increase

-80%

Reduction of administrative work

+55%

Logistics and production management capacity

BE PART OF THE FUTURE

Clients around the World