TCI Cutting puts industry 4.0 within the reach of companies

Industry 4.0

Digitally connected manufacturing is key to increasing the levels of productivity and efficiency, also achieving a completely transparent process since these digital solutions and automation provide production information in real time.

All this provides our customers with the possibility of obtaining a tailor-made production, totally individualized and adapted to their needs. The software designed and created by TCI Cutting enables the production of totally individualized products with lower cost and delivery time, determining factors to maintain competitiveness.

Industrial production must adapt and cannot escape to the new reality of Industry 4.0, a production model in which all elements of the chain must be interconnected and communicate with one another.

Precisely the ability to store, process and exchange data is one of the keys of Industry 4.0. Internet and technological capabilities have made it possible for us to access more and more information, and can process and share it at a tremendous speed. This has transformed the way we consume and the way we relate.

Among the advantages that the digitization of the manufacture is the ability to adapt to the demand in a constant way, personalized service to the customer, one-to-one after sales service, design, produce and sell products in less time or create shorter and more profitable production series.

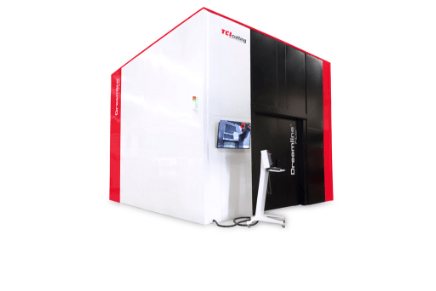

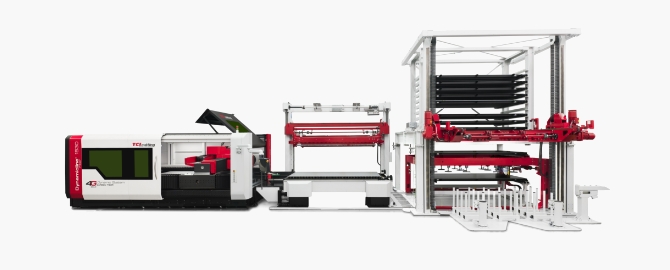

Industry 4.0 is available to all our customers thanks to PROmanager and SMARTTOUCH, two powerful manufacturing management systems created by TCI Cutting with the aim of optimizing the use of our cutting machines in a fully digitized industrial environment.

PROmanager and SMARTTOUCH are two software systems developed by TCI Cutting to configure a factory 4.0 with optimized production.

PROmanager

Tools like the PROmanager make it possible for companies to enter industry 4.0 that is revolutionizing the reality of companies. This software brings together all the information that a company needs, from employees, to the positions of processing materials, stocks and expedition.

PROmanager digitally connects with all the elements of the company, collecting and sending data and information to and from them, thus achieving control and optimization of each of the processes. The final result will always be a greater profitability of the company.

This powerful software provides our clients with enough data of their industrial task to be able to make vital decisions and generate an optimal work flow. Multi-user and unlimited licenses, PROmanager allows full control of permissions and access to functions and sections of the program.

Designed in a responsive web environment, it is accessible from all types of devices, smartphones and tablets.

SMARTOUCH

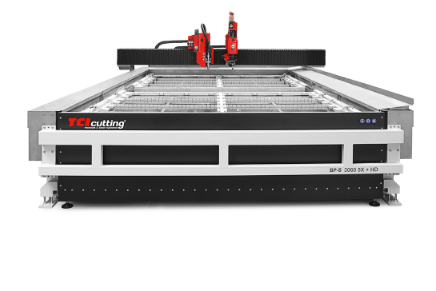

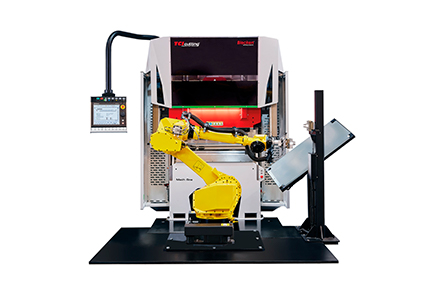

With extensive experience in the manufacturing of waterjet and laser cutting machines, the TCI Cutting team of engineers have designed a new element to achieve total digitalization of the work environment. SMARTTOUCH is an agile and intuitive software that facilitates the operation of the personnel of the manufacturing process and digitally connects with the rest of the company’s elements, collecting and sending data from industrial processes.

La combinación de nuestras máquinas con estas soluciones de software especializado posibilitan una fabricación digital totalmente integrada en las innovaciones propias de la industria 4.0.

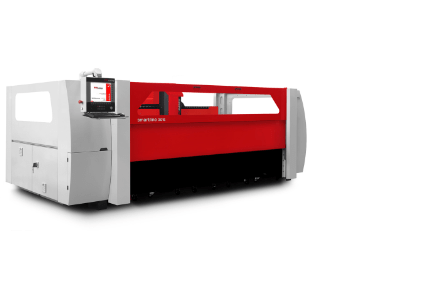

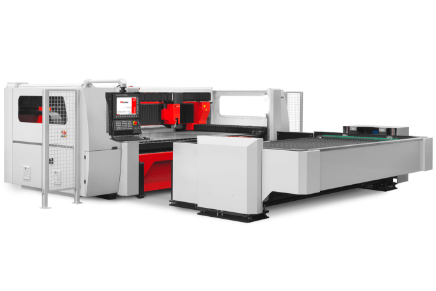

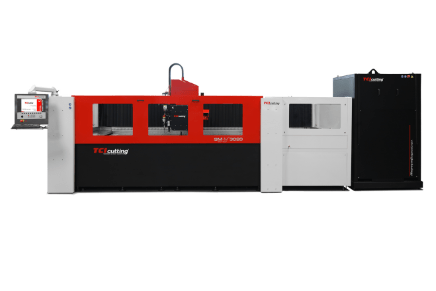

The combination of our machines with these specialized software solutions enables digital manufacturing fully integrated into the innovations of the industry 4.0.