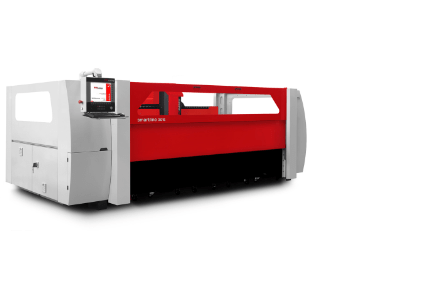

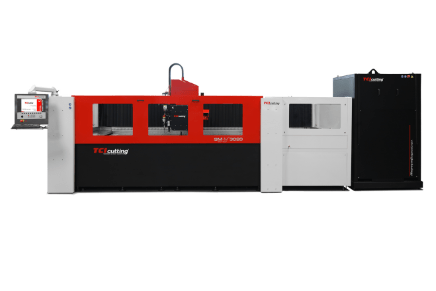

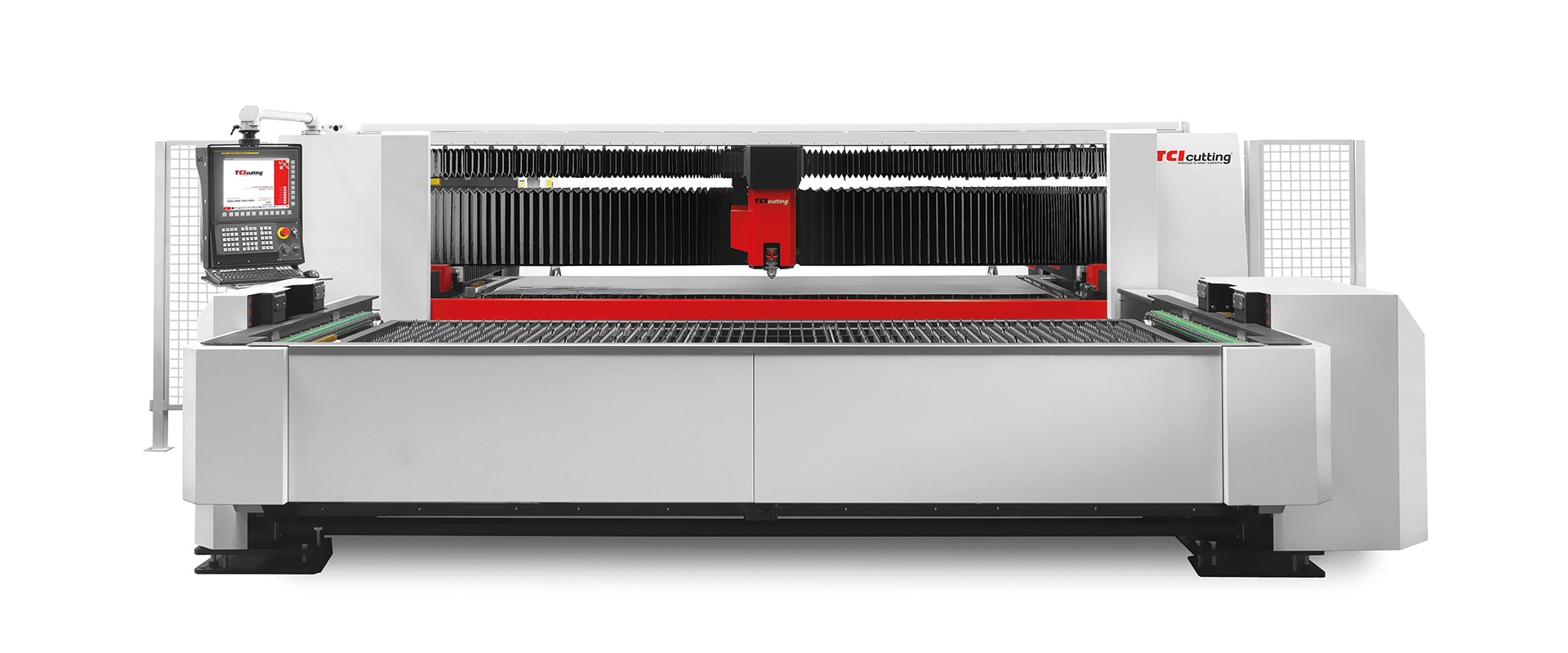

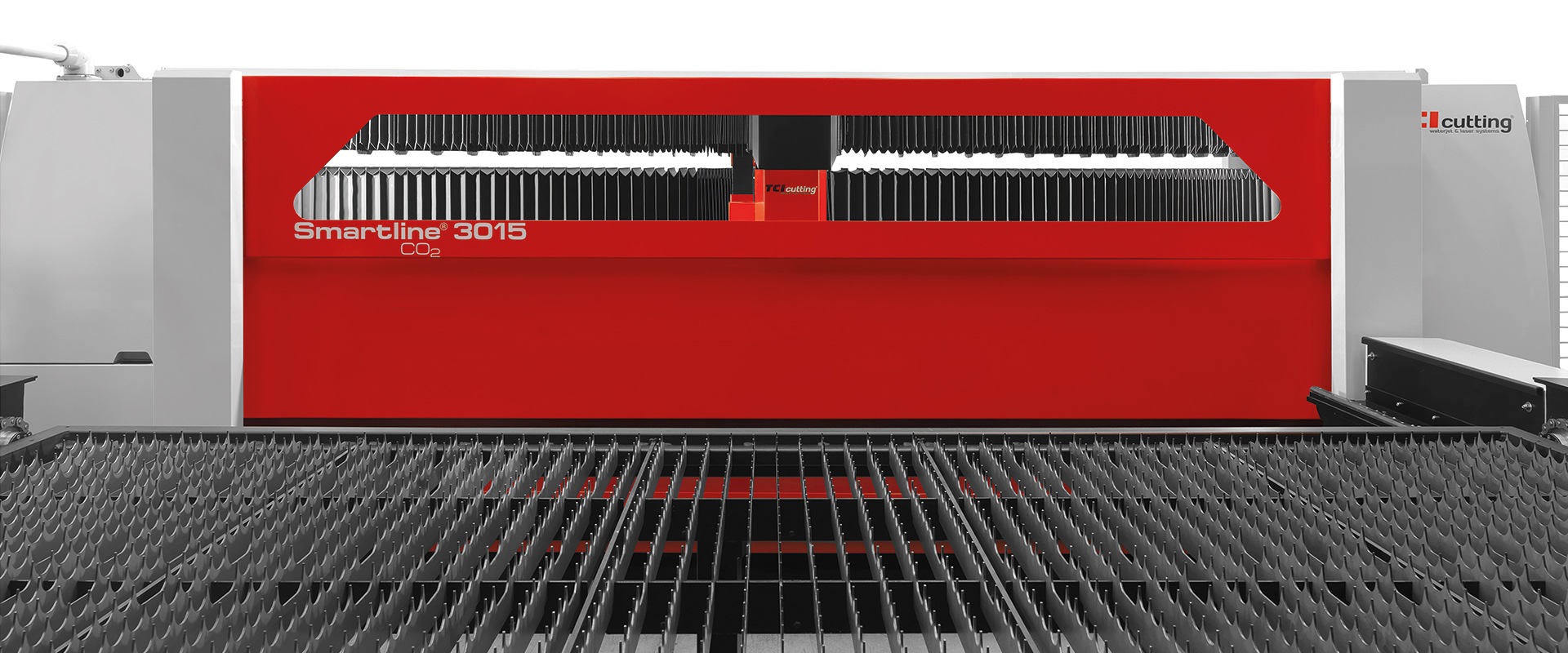

Smartline CO2®

OUR MOST PRODUCTIVE MACHINE IN CO2

This series offers great cutting quality in both thin and thick materials. It is the perfect series for cutting wood, acrylic, glass, methacrylate, paper, textiles, plastics, leather and stone.

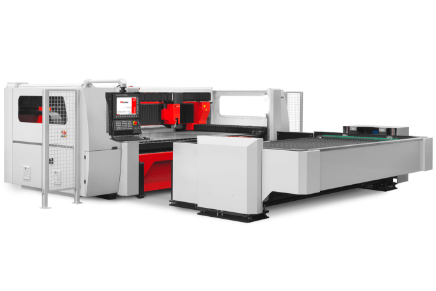

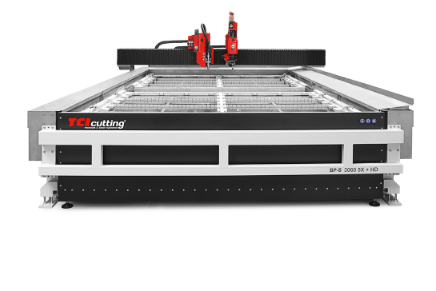

Technical

Specifications

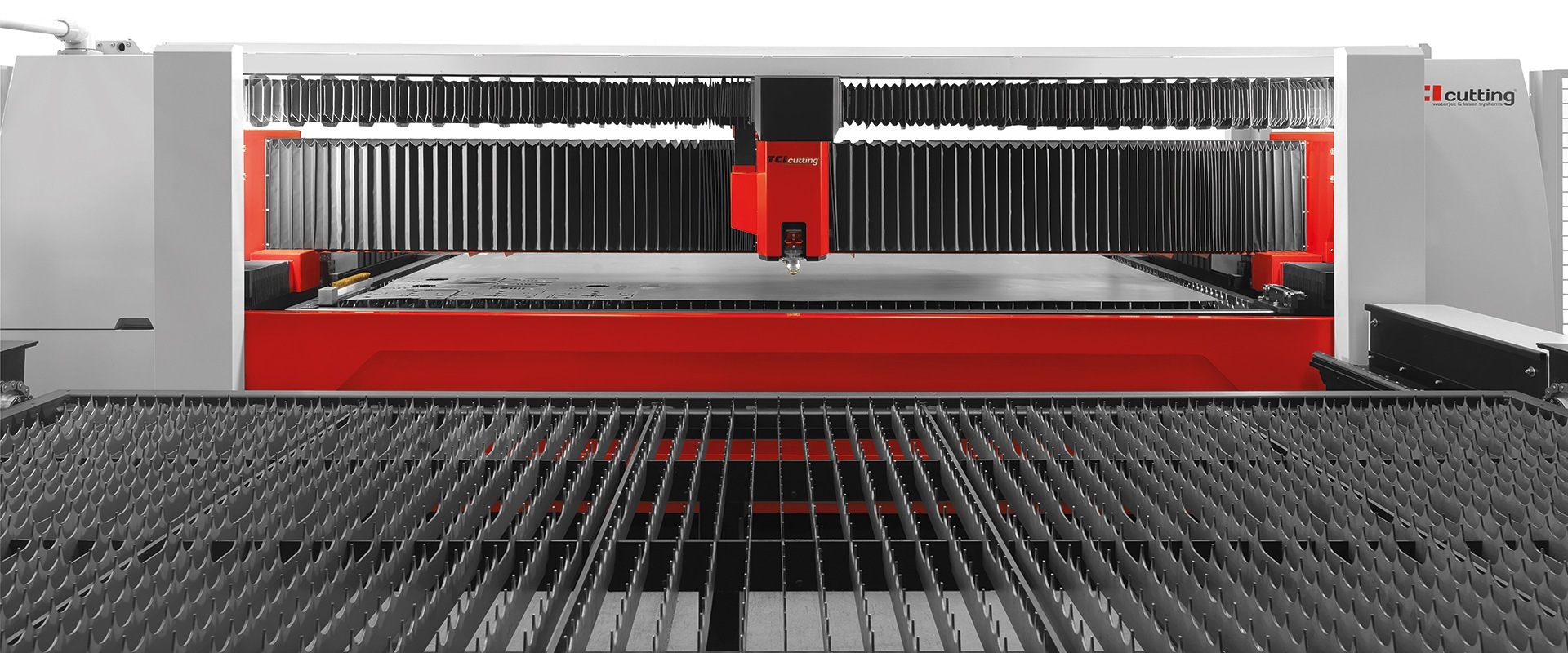

| Feature | |

|---|---|

| Maximum load | 950 kg |

| Heads | 1 |

| Maximum simultaneous positioning speed | 160m/min |

| Machine tolerance VDI/DGQ3441 | ± 0.05 mm/m |

| Repeatibility | ± 0.025 mm |

| Power output | From 1.000 W to 3.000 W |

| Dimensions | 3.000x1.500x100 mm |

| Smoke extraction system | Inclusive |

| Cooling system | Inclusive |

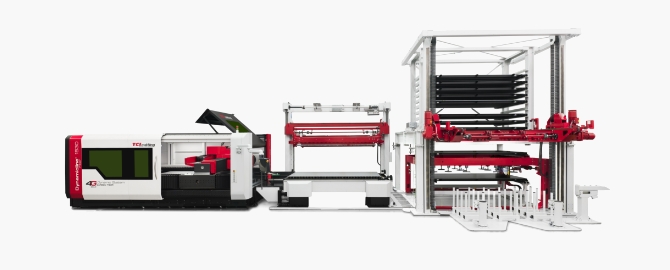

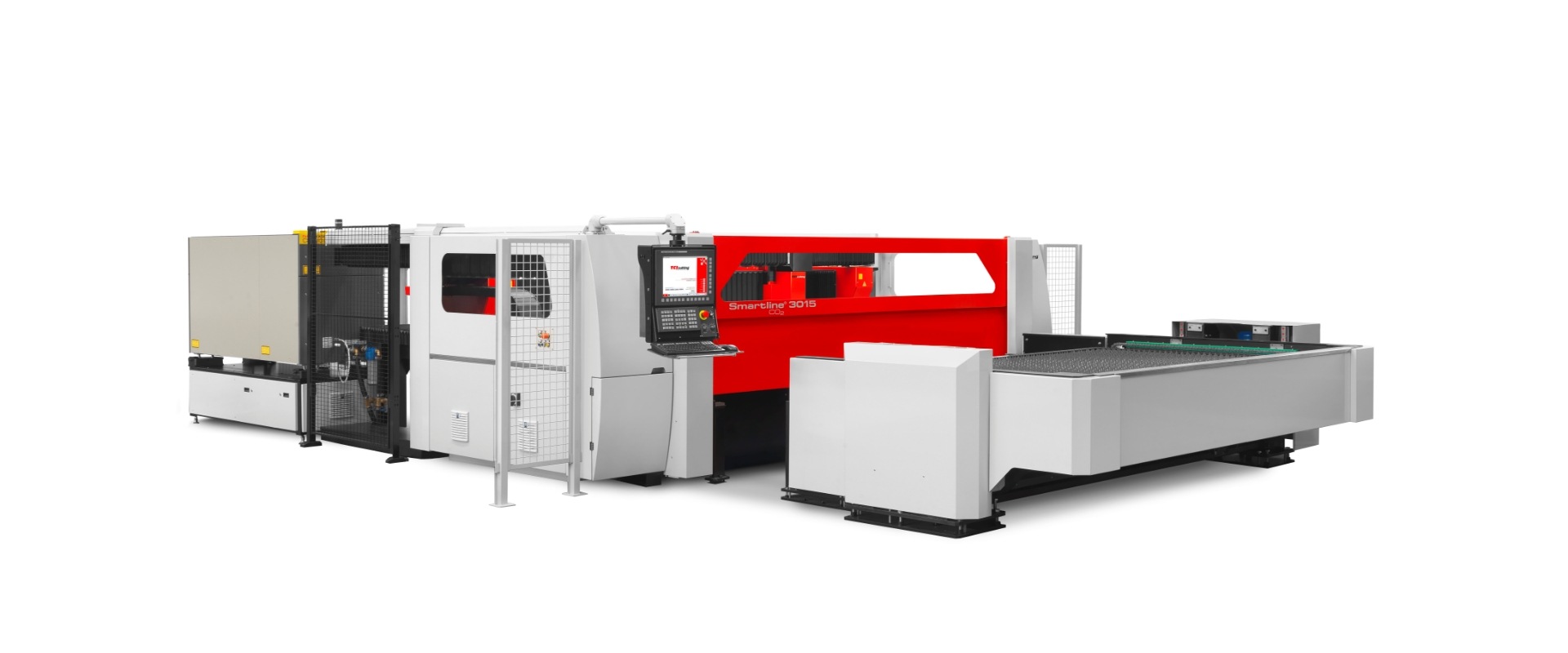

| Automatic table exchanger | Optional |

| Automatic loader and unloader | Optional |

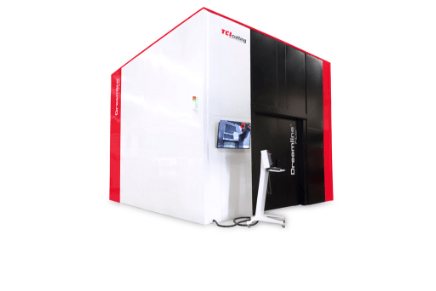

STATE-OF-THE-ART

TECHNOLOGY

WHY

TCI CUTTING

Intelligent

SoftwareAutonomous decision making.

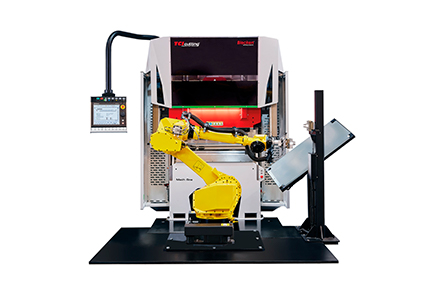

Tailor-made

automationEfficiency. One client, one solution.

Predictive

technical assistanceMaximum efficiency without workdowns. Expert team.

TCI

TrainingTailor-made training certificate programs.

Implementation

of productive processes Optimisation. Full integration. Industry 4.0.

BE PART OF THE FUTURE

Clients around the World

TCI CUTTING

WE ADVISE YOU

Contact our technical team.

A specialist will contact you as soon as possible to advise you

personally on everything you need.

Download Technical Data

Smartline CO2

Download the complete catalog of solutions