Smarttube Fiber: less consumption and more quality in tube cutting

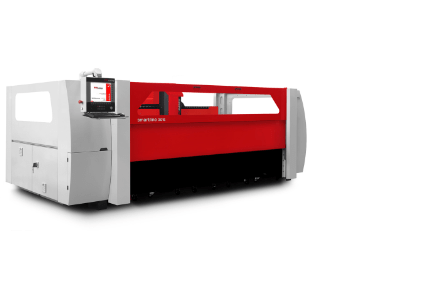

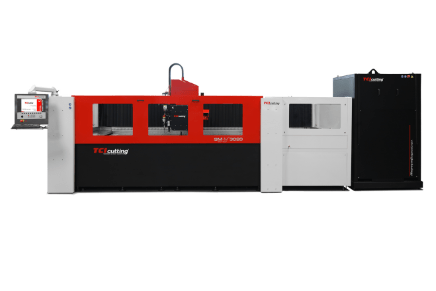

Very low energy consumption with unbeatable cutting quality is the value proposition of Smarttube, the fiber laser cutting machine for tubes that TCI Cutting has just launched on the market

The fiber laser cutting technology is extended to tube cutting, allowing new applications of this technology which can favor countless sectors. Smarttube Fiber, designed and manufactured by TCI Cutting, is capable of processing tubes from 20 millimeters to 220, as well as square profiles. Furthermore, thanks to its five axes cutting head the machine allows cutting of both open and closed profiles.

The technical characteristics of the Smarttube make it the most versatile and flexible tube cutting machine on the market, since it offers a complete solution, with very low energy consumption and unmatched cutting quality.

Open Days 2017

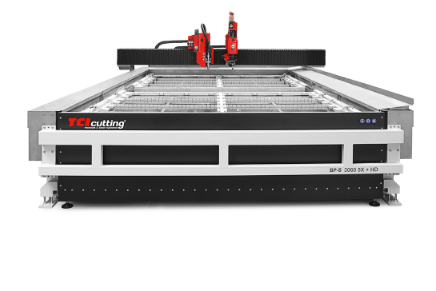

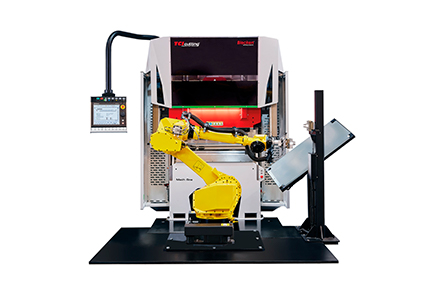

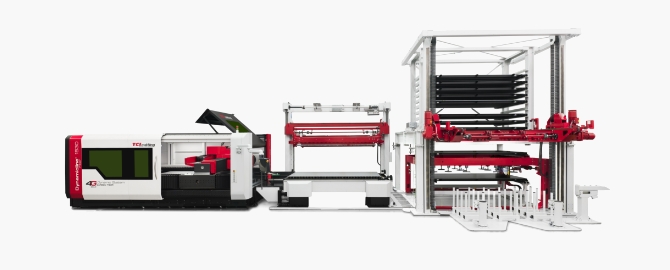

During the Open Days of TCI Cutting, this new machine was presented to the public. It was very popular among the attendees, who were able to verify the Smarttube’s capabilities. This advanced machine allows both manual and semi-automatic loading of up to 6 meters (40kg / m), in addition to multiple unloading controlled from the Central Numerical Control, CNC.

Features of the Smarttube tube cutting machine

Some of the highlights of this new high performance fiber laser cutting system for tubes:

- Easy to use touch panel compatible with industrial ethernet

- Loader capable of handling different types of pipes and both open and closed profiles

- Modular conveyor belt unloader

- CAD / CAM integrated with the possibility of importing external files and including system of drawing, optimization and nesting of tubes and profiles.

- System with closed database for cutting technology tables.

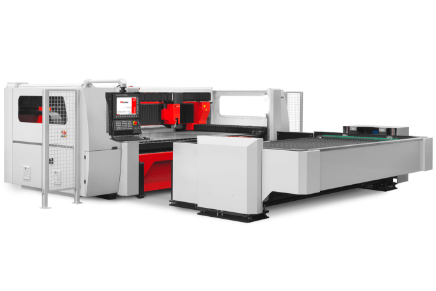

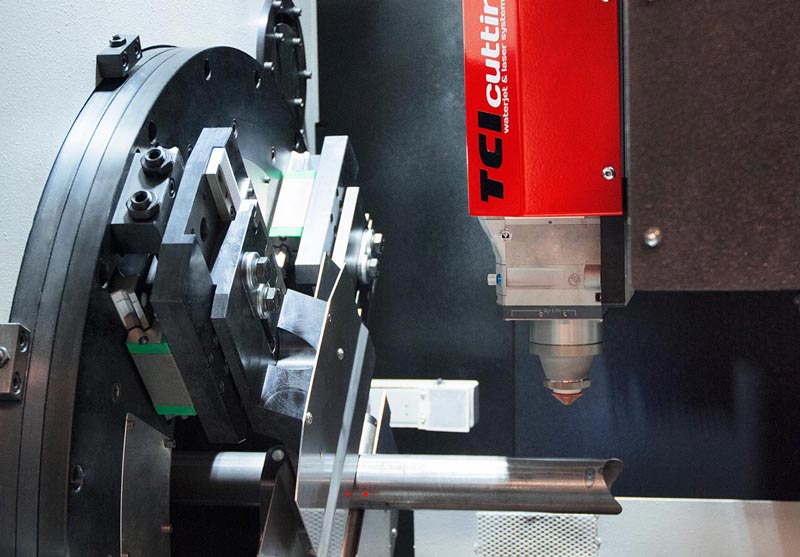

Cutting heads

The new fiber laser cutting machine allows the installation of 2D and 3D heads that provide flexibility and versatility to perform all kinds of cuts and finishes.

Speed

Speed is another of the highlights of the Smarttube Fiber with an acceleration of 9’8 m / s2 (1G) and a maximum speed simultaneous positioning of 50m / min, parameters that increase productivity significantly. The IPG resonator of the machine works with powers of 1 to 3 kw.

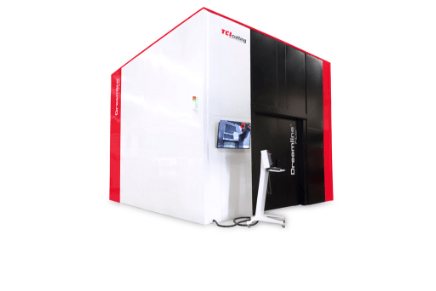

Security

This fiber laser tube cutting machine is fully enclosed to ensure maximum protection of the operator. It also includes an effective system for changing high to low gas pressure and a capacitive sensor with a high pressure cutting head. Optionally, it can incorporate a piercing system, smoke extraction or automatic focal control. The minimum load length is 3000 millimeters and the maximum unloading length is 3000 millimeters.

The fiber laser cutting technology expands the possibilities of configuration and design of tubes and profiles, being able to adjust to the needs and specific requirements of each client depending on the application sector, from automotive to mechanical construction and many others.