Power, speed and energy saving

Power, speed and energy saving

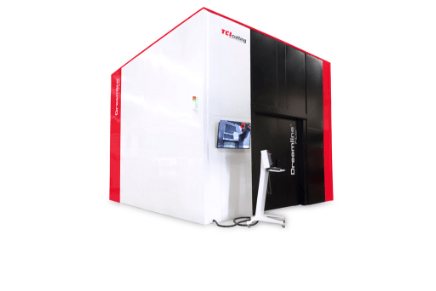

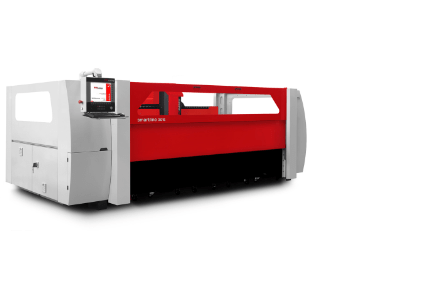

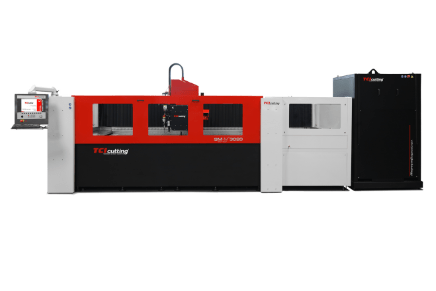

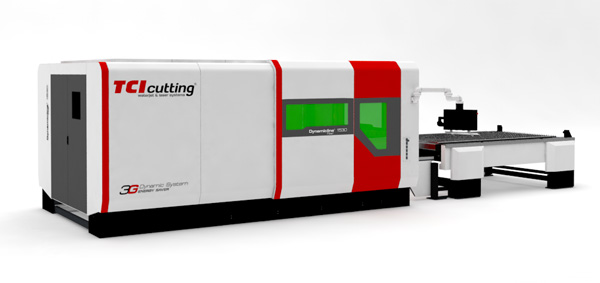

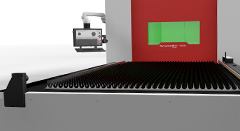

TCI Cutting Dynamicline Fiber is pure power, without losing sight of electrical and productive efficiency. With versions that reach up to 12 kW of cutting power and its design that includes linear motors, the possibility of cutting thicknesses of up to 30 mm reaching an acceleration of 3G and an accuracy of 3 microns. Travel speeds of up to 340 m / min guarantee the highest productivity for the most demanding customers.

The team of engineers of TCI Cutting has achieved a cutting system, which combines the necessary features to produce the most complex cutting work and with the most innovative cutting options (automatic nozzle change, artificial vision camera …), never seen until this moment in a laser cutting system with fiber source.

The energy saving and the cutting speed, added to the laser power, were the three main premises when designing the Dynamicline Fiber system, thus achieving a compact system of high performance for high productions.

- Acceleration rate: 29,4 m/s2 (3G)

- Maximum simultaneous positioning speed: 340m/min

- Precision: ± 0.05 mm

- Energy efficiency: greatly reduced power consumption

- Excellent cutting quality for both fine and medium thickness sheets

- IPG Resonator. Power output from 1kW to 8kW

- Precitec Light Cutter cutting head for power output up to 2kW

- Precitec / Highyag cutting head for power output greater than 2kW

- Fully enclosed and cabined machine to ensure maximum protection for the operator

- Effective system to change from high to low gas pressure

- Capacitive Sensor, high pressure cutting head

- TCI Cutting parameter tables

- Pre-cut protective film

- Power output control function for automatic nesting and machining (corners, lead-ins)

- Automatic time and cost calculation for pieces

- Network connection via external PC

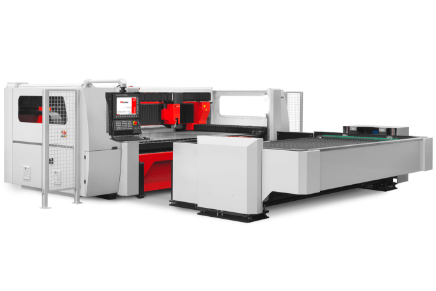

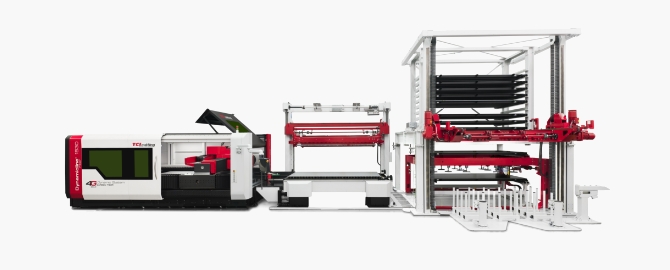

- Automatic table exchanger (included for some models)

- Smoke extraction system (included for some models)

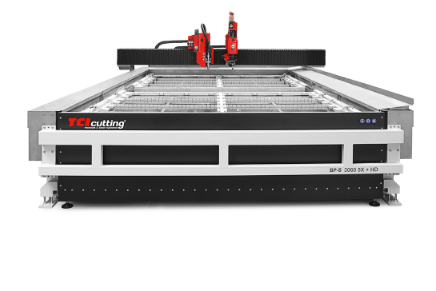

- Sheet metal detection system, using artificial vision software.

- 3 Point reference sensor (sheet rotation detection)

- Piercing Sensor (optional)

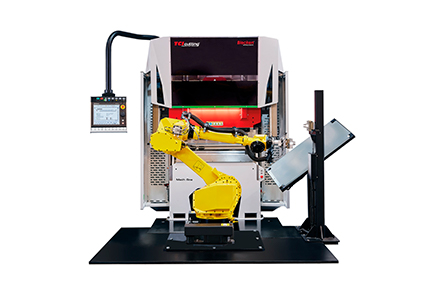

- Collection of workpieces and trimmings

- Dual proportional valve control system for different gas pressures and special system for high pressure cutting

- CNC Fanuc 31iLB

- Sistema refrigeracion

- Automatic nozzle cleaning

- Automatic focus control

- MultiTouch Screen with remote control

- Ultrafast Heightregulation

- TCI Smart Touch 6.0

- TCI Fly Cutting 3.0

- TCI Fast Piercing 2.0

- TCI Automatic cutting system 3.2: (Automation of job lists)