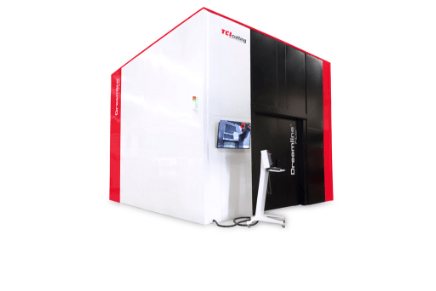

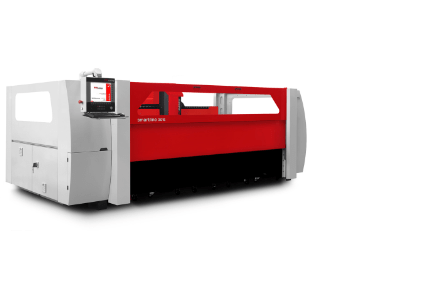

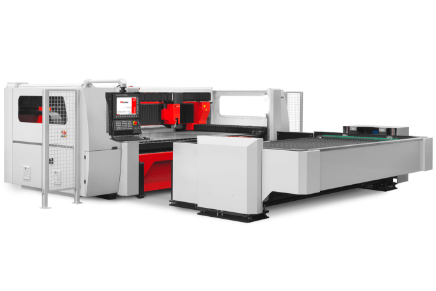

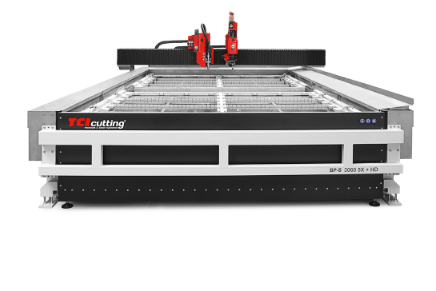

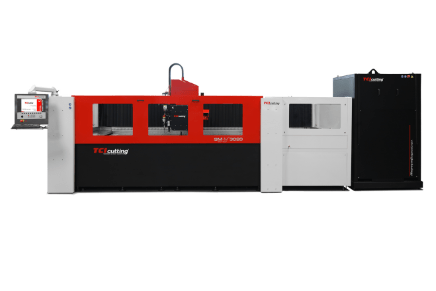

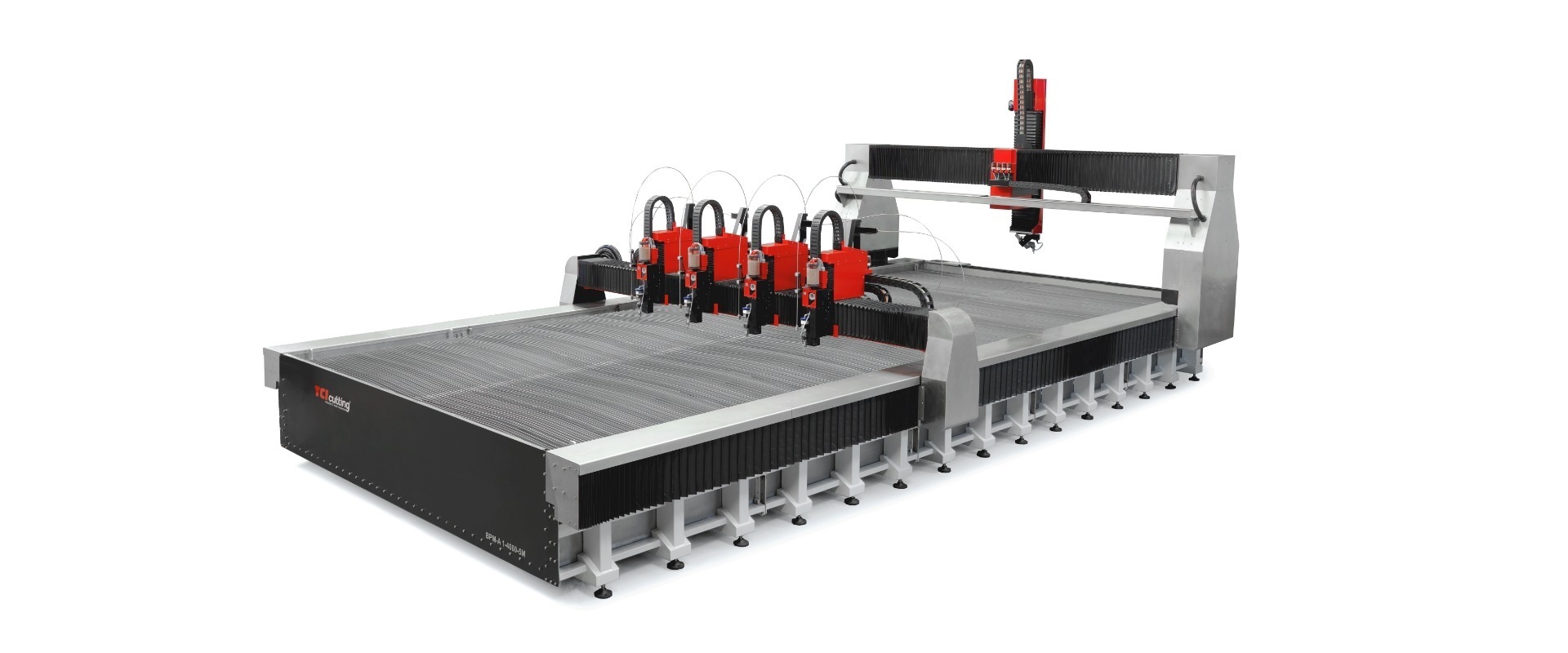

BP-M®

OUR MOST COMPACT MACHINE

To the advantages of the standard series is added the plus of flexibility for customers cutting thick and large-area materials. Strength and flexibility.

Technical

Specifications

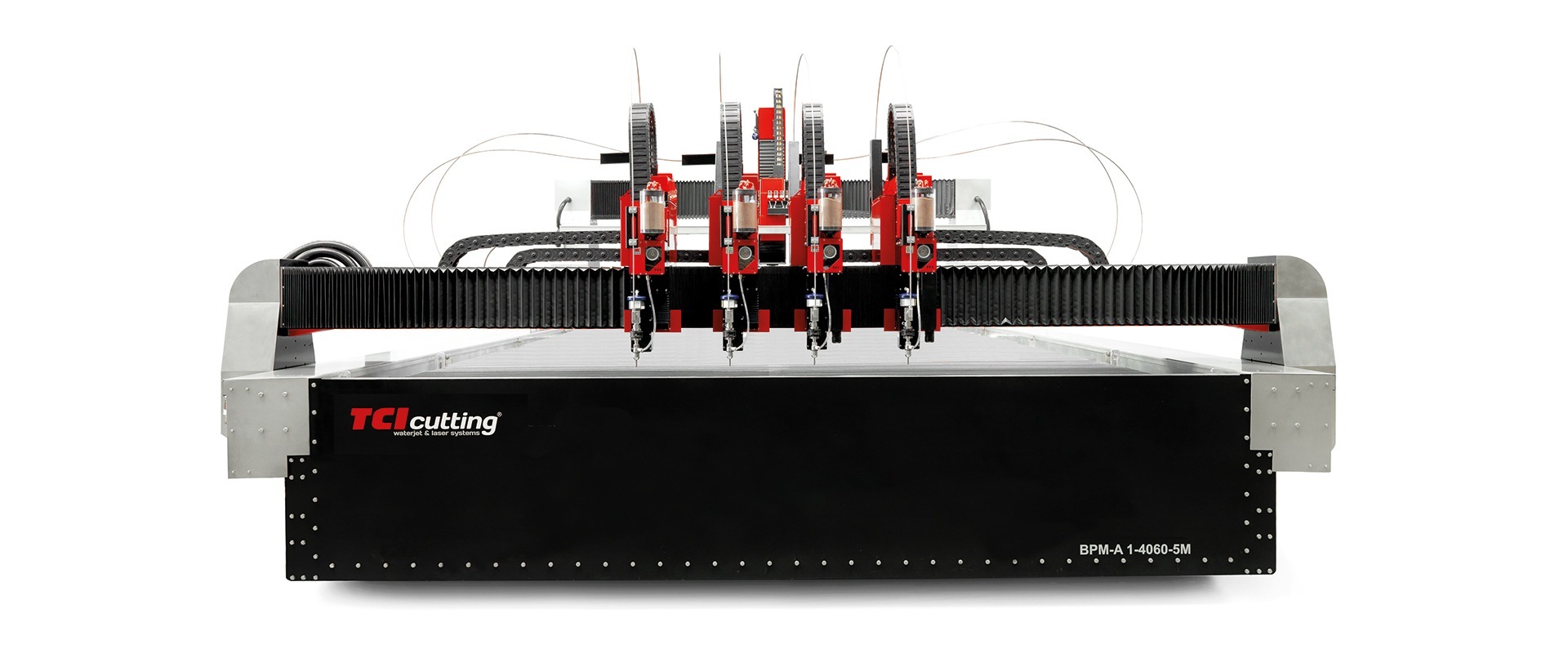

| Feature | BP-M 2040 | BP-M 3020 | BP-M 3060 | BP-M 3080 | BP-M 30120 | BP-M 4060 | BP-M 4080 | BP-M 40120 |

|---|---|---|---|---|---|---|---|---|

| Maximum thickness of the part | 200 mm | 200 mm | 200 mm | 200 mm | 200 mm | 200 mm | 200 mm | 200 mm |

| Maximum permitted load | 1.000 kg/m2 | 1.000 kg/m2 | 1.000 kg/m2 | 1.000 kg/m2 | 1.000 kg/m2 | 1.000 kg/m2 | 1.000 kg/m2 | 1.000 kg/m2 |

| Number of cutting heads | 1 to 4 | 1 to 4 | 1 to 4 | 1 to 4 | 1 to 4 | 1 to 4 | 1 to 4 | 1 to 4 |

| Maximum number of bridges | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Simultaneous max positioning speed | 85 m/min | 85 m/min | 85 m/min | 85 m/min | 85 m/min | 85 m/min | 85 m/min | 85 m/min |

| Maximum cutting speed | 20 m/min | 20 m/min | 20 m/min | 20 m/min | 20 m/min | 20 m/min | 20 m/min | 20 m/min |

| Machine tolerance according to VDI / DGQ 3441 | ± 0.05 mm/m | ± 0.05 mm/m | ± 0.05 mm/m | ± 0.05 mm/m | ± 0.05 mm/m | ± 0.05 mm/m | ± 0.05 mm/m | ± 0.05 mm/m |

| Repetition accuracy | ± 0.025 mm | ± 0.025 mm | ± 0.025 mm | ± 0.025 mm | ± 0.025 mm | ± 0.025 mm | ± 0.025 mm | ± 0.025 mm |

| Dimensions | 2000x4000x200 mm | 3000x2000x200 mm | 3000x6000x200 mm | 3000x8000x200 mm | 3000x12000x200 mm | 4000x6000x200 mm | 4000x8000x200 mm | 4000x12000x200 mm |

| MODELS | Dimensions |

|---|---|

| BP-M 2040 | 2000x4000x200 mm |

| BP-M 3020 | 3000x2000x200 mm |

| BP-M 3060 | 3000x6000x200 mm |

| BP-M 3080 | 3000x8000x200 mm |

| BP-M 30120 | 3000x12000x200 mm |

| BP-M 4060 | 4000x6000x200 mm |

| BP-M 4080 | 4000x8000x200 mm |

| BP-M 40120 | 4000x12000x200 mm |

STATE-OF-THE-ART

TECHNOLOGY

WHY

TCI CUTTING

Intelligent

SoftwareAutonomous decision making.

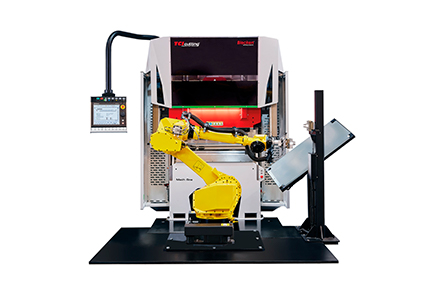

Tailor-made

automationEfficiency. One client, one solution.

Predictive

technical assistanceMaximum efficiency without workdowns. Expert team.

TCI

TrainingTailor-made training certificate programs.

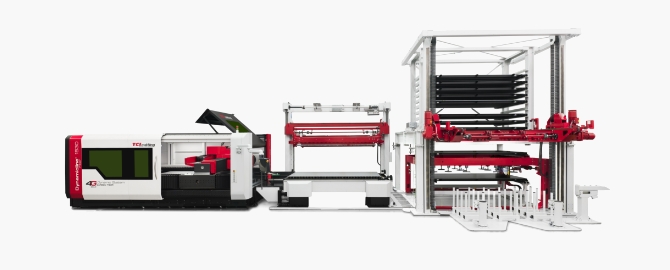

Implementation

of productive processes Optimisation. Full integration. Industry 4.0.

BE PART OF THE FUTURE

Clients around the World

TCI CUTTING

WE ADVISE YOU

Contact our technical team.

A specialist will contact you as soon as possible to advise you

personally on everything you need.

Download Technical Data

BP-M Series

Download the complete catalog of solutions